Table of Contents

ToggleMaterial Submittals in the HVAC Project Lifecycle

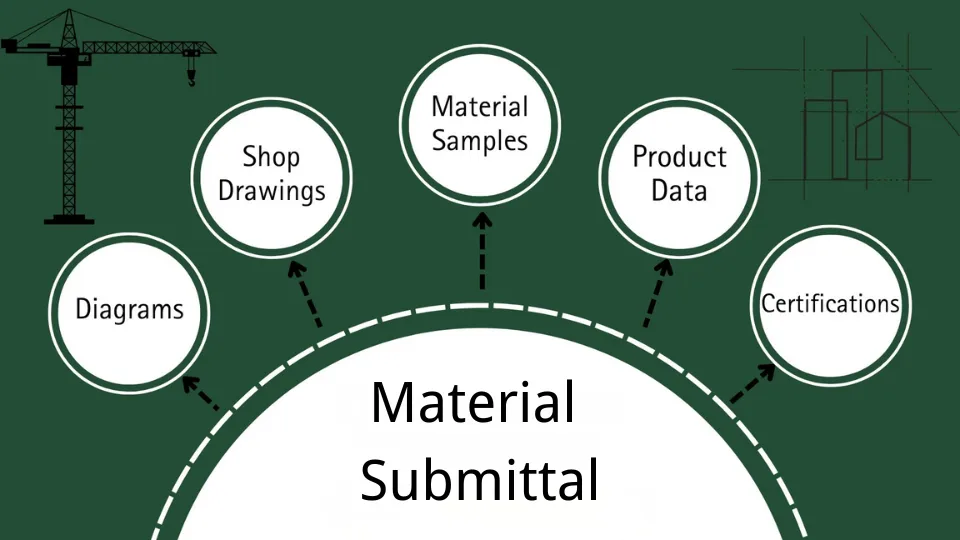

Before a single duct hanger goes up, the project team needs confidence in every key product: fans, dampers, ducts, access doors, fire-stopping, louvers, and controls. Material submittals provide that confidence.

A material submittal package gives the owner and consultant a structured way to check that proposed products:

- Match the specification and drawings

- Meet performance and safety requirements

- Come from acceptable manufacturers with valid certifications

For ventilation and smoke-control work, strong submittal discipline also shows how seriously a company treats quality and FIRE SAFETY.

What Owners and Consultants Expect to See

Material submittals for HVAC and ventilation equipment usually follow a predictable structure, even if each project uses a different template.

Technical and performance documentation

Reviewers want enough information to compare the proposed item against the spec, without guessing. A typical package includes:

- Data sheets with model numbers, sizes and ratings

- Performance curves (airflow vs pressure, sound levels, efficiency) for fans and silencers

- Construction details and materials, including coatings and linings

- Temperature, pressure, and leakage ratings where relevant

Clear highlighting of the selected duty point helps engineers verify that AIRFLOW CONTROL targets remain intact.

Compliance, testing, and certification

Many ventilation products carry code and standard requirements. Submittals show how each item complies, for example:

- Fire damper ratings and test reports from recognized labs

- Smoke-control component approvals and temperature classifications

- IP or NEMA ratings for outdoor or exposed equipment

- Acoustic test reports for silencers and acoustic louvers

This section links project requirements to independent testing, not only manufacturer claims.

Samples, finishes, and accessories

For visible or high-risk components, owners and consultants often ask for:

- Physical samples of grilles, louvers, or access doors

- Finish samples for coatings and aluminum profiles

- Examples of nameplates, labels, and inspection tags

These pieces help confirm appearance, durability, and identification before full production.

How a Ventilation Material Submittal Moves Through the Project

A good process keeps decisions transparent and traceable. For ventilation equipment, the workflow often looks like this:

- Specification review

The contractor and supplier study the spec, drawings, and schedules to identify required submittals and any alternative options. - Package assembly

YAOAN VENTILATION prepares product data, performance information, certificates, and sample lists in the agreed format. - Internal contractor review

The main contractor’s engineering team checks each package for completeness and consistency with the overall design. - Submission to consultant and owner

The team sends digital (and sometimes hard-copy) submittals through the project’s document-control platform with clear references to drawing and spec sections. - Technical review and comments

Consultants review the package, compare it with requirements, and issue comments: approved, approved with comments, or revise and resubmit. - Clarifications and revisions

The contractor and supplier address comments, answer technical questions, and, if needed, propose alternatives with full justification. - Final approval and record

Once approved, the submittal becomes the reference for procurement, fabrication, and inspection. Later O&M manuals and as-built records use the same data.

This sequence helps avoid disputes on site when inspectors ask, “Who approved this fan or damper?”

Material Submittals for Ventilation and Fire-Safety Components

Ventilation projects include several product groups that benefit from especially careful submittal treatment.

- Fans and jet fans – Need clear performance curves, motor data, temperature ratings for smoke duty, sound power levels, and mounting details.

- Fire and smoke dampers – Require test reports, installation details for shafts and walls, blade and frame materials, and actuator information.

- Ductwork systems – Need information on gauges, seam types, leakage class, insulation, and external corrosion protection.

- Acoustic elements – Silencers and acoustic louvers must show octave-band performance and pressure drop at design velocities.

- Controls and panels – Require I/O lists, schematics, front-panel layouts, and integration notes for the building automation system.

Aligning these submittals early helps keep coordination drawings, factory testing, and commissioning consistent.

How YAOAN VENTILATION Strengthens the Submittal Process

YAOAN VENTILATION treats material submittals as technical deliverables, not only paperwork. Our approach typically includes:

- Project-specific submittal indexes that tie each product to drawing tags and schedules

- Clean, legible data sheets with the selected configuration clearly marked

- Grouping of related items (for example, fans with matching silencers, dampers, and accessories) so reviewers see complete systems

- Cross-references from submittals to relevant standards and test reports

When the package arrives on the consultant’s desk, they can check engineering decisions quickly instead of searching for missing information. That efficiency reduces review cycles and supports the project schedule.

Typical Pitfalls and How to Avoid Them

Several recurring issues slow down approvals on mechanical projects:

- Generic catalog cuts that do not highlight the selected model or duty point

- Missing certificates or expired test reports for fire and smoke-related items

- Uncoordinated alternatives that ignore shaft sizes, power availability, or acoustic limits

- Inconsistent naming between submittals, drawings, and BIM models

Simple discipline stops most of these problems. Using consistent tags, checking completeness before submission, and pairing each product with the right test data protects both schedule and reputation.

FAQ

How to prepare a material submittal?

To prepare a material submittal, identify the items required by the spec, then gather data sheets, performance information, certificates, and any samples. Organize them under a clear cover sheet with project, drawing, and specification references. Before sending, review the package internally to confirm that the proposed products meet all technical and code requirements.

What is the purpose of a submittal?

A submittal gives owners and consultants a chance to verify that proposed materials and equipment comply with project requirements before installation. It creates a documented approval path, reduces on-site changes, and supports quality, safety, and warranty obligations.

What is an example of a submittal?

Examples include a fan submittal with performance curves and motor data, a fire damper submittal with rating certificates and installation details, or a louver submittal with free area, pressure drop, and finish information. Each example links real products to the project’s design intent.

What is a material submission?

A material submission, or material submittal, is the formal package the contractor sends for approval of products. It contains technical data, certifications, samples, and any deviations for review. Once approved, it becomes the reference for purchasing and inspection.

What is a material submittal?

A material submittal explains exactly which product the contractor plans to supply in place of a generic item in the drawings or spec. It proves that the selected model meets performance, safety, and quality requirements, and it records consultant and owner approval before installation.

What are the 7 stages of construction?

Different frameworks exist, but many projects follow stages such as concept, design development, procurement, construction planning, site construction, testing and commissioning, and handover with operation. Material submittals sit mainly in the procurement and early construction stages and influence commissioning and handover quality.

Who prepares submittals?

Trade contractors and their suppliers prepare most submittals. The main contractor coordinates, reviews for completeness, and then forwards them to the consultant or owner for approval. Manufacturers like YAOAN VENTILATION support the process by supplying accurate, project-specific technical documentation and certifications.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our portfolio includes fans, fire dampers, smoke control components, silencers, and precision-built aluminum ventilation parts, all supported by structured material submittals, FAT records, and O&M documentation. By combining solid engineering with clear approval packages, YAOAN VENTILATION helps projects control risk, streamline reviews, and maintain confidence from design through long-term operation.