Table of Contents

ToggleSupplying Air to Tall and Deep Spaces

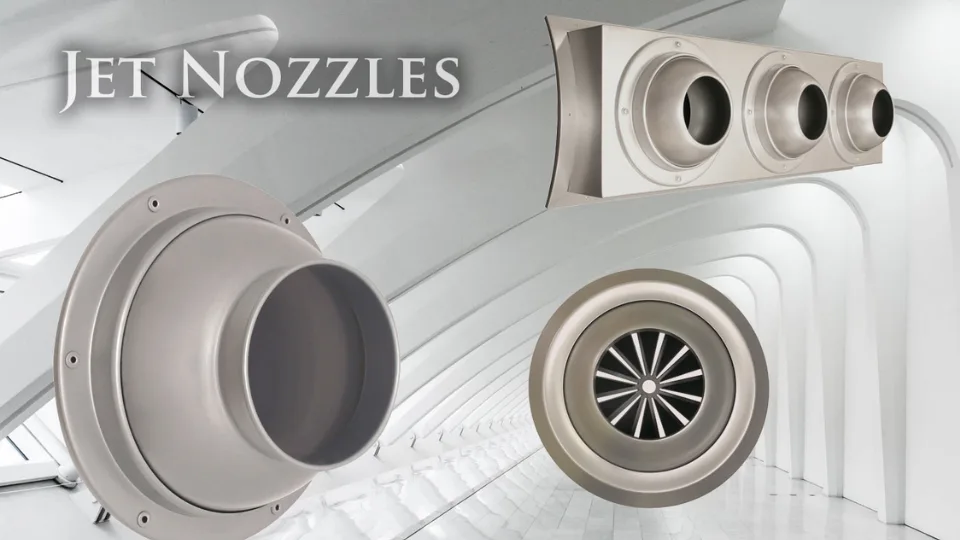

Atriums, exhibition halls, and large industrial bays rarely behave like simple rooms. Supply air that works in a standard office diffuser often stalls high above the occupied zone or drops as a cold draft. Jet nozzle diffusers offer a way to bridge that distance with controlled, long-throw airflow.

They create tight, high-velocity jets that reach far into the space, then mix strongly with room air. With correct design, that jet spreads enough to cover the occupied area while still protecting comfort, noise limits, and AIRFLOW CONTROL targets.

How a Jet Nozzle Diffuser Shapes the Air Stream

Jet nozzle diffusers focus on throw and induction rather than only on low noise at short range.

Jet formation and induction

Inside the diffuser, the air exits through a contoured nozzle rather than a flat face. That geometry:

- Accelerates the air into a compact jet with a defined direction.

- Maintains velocity over a longer path than a standard ceiling diffuser.

- Pulls surrounding room air into the jet, which increases total flow and improves mixing.

As the jet travels, velocity gradually drops and the temperature difference between supply air and room air reduces. People in the occupied zone then feel stable conditions instead of stratified layers or direct cold streams.

Adjustable direction and pattern

Most jet nozzle diffusers offer directional adjustment. A technician can tilt the nozzle to:

- Aim the jet horizontally across an atrium.

- Direct air slightly downward toward a distant occupied zone.

- Compensate for local obstructions such as beams, lighting, or cranes.

This adjustability gives flexibility when real site conditions differ from the early design model.

Where Jet Nozzle Diffusers Solve Practical Problems

High-ceiling public spaces

In atriums, airport halls, and shopping centers, jet nozzles often mount on high walls or overhead structures. They:

- Deliver air across open volumes without excessive ductwork.

- Help control temperature gradients between floor and roof levels.

- Integrate with architectural design better than large visible ducts in sensitive zones.

Correct aiming ensures that air sweeps through occupied walkways and waiting areas instead of remaining trapped near the ceiling.

Industrial halls and process areas

Factories, sports halls, and warehouses also benefit from long-throw diffusers. In these buildings, jet nozzles can:

- Reach workstations under cranes or near high racking.

- Support spot cooling in zones with process heat loads.

- Reduce stratification that wastes heating and cooling energy.

Engineers often combine jet nozzles with return grilles positioned to encourage full-room circulation instead of short-circuiting.

Key Performance Data for Jet Nozzle Selection

Choosing a jet nozzle diffuser means reading more than one line in a catalog. Several data points matter together.

Throw, temperature difference, and mounting height

Manufacturers normally publish throw data for different airflows and temperature differences. Designers look for:

- Throw distance to a defined terminal velocity, often around 0.25–0.5 m/s in the occupied zone.

- Limits on supply air temperature difference to avoid drafts at that throw.

- Recommended mounting heights and angle ranges.

The goal is to match nozzle size and airflow so that the jet arrives in the occupied zone with acceptable velocity and temperature.

Sound and pressure drop

Jet nozzles concentrate air, so they can create higher sound levels near the outlet if not sized correctly. Selection should check:

- Sound pressure levels at design flow for the receiver locations.

- Static pressure requirement at the diffuser inlet.

Balancing acoustics and pressure keeps both comfort and fan energy under control.

Compatibility with duct layouts and static pressure boxes

Jet nozzles can connect directly to ducts or to static pressure boxes concealed in the ceiling void or wall cavities. Coordination with duct routing, ceiling support, and access requirements ensures that the chosen diffuser can actually deliver its rated performance on site.

Design and Installation Considerations

Matching nozzle layout to room air patterns

An effective scheme starts with the room, not with the product:

- Identify occupied zones and sensitive areas such as entrances or seating clusters.

- Plan jet paths so they overlap slightly and avoid direct impact on fixed workstations.

- Keep a clear line of sight between nozzle outlets and the intended target area.

CFD studies or experience-based rules can help refine these patterns in complex spaces.

Integration with heating, cooling, and smoke control

Jet nozzle diffusers often work within a broader system:

- In cooling mode, they must distribute air without creating cold downdrafts.

- In heating mode, designs may use different angles or reduced flows to avoid hot air trapped at roof level.

- In some projects, the same air paths influence smoke behavior, so designers check compatibility with FIRE SAFETY strategies.

Control sequences, damper settings, and fan speeds should reflect these seasonal and emergency roles.

Maintenance and adjustment

Over the life of a building, uses change. Jet nozzles stay effective when teams can:

- Access mounting points safely for cleaning and re-aiming.

- Confirm that adjustment mechanisms still hold their position.

- Update O&M documentation when orientation or flow settings change.

Good documentation keeps later modifications from undermining carefully planned AIRFLOW CONTROL.

FAQ

What is a jet diffuser?

A jet diffuser is an air outlet that forms a focused, high-velocity air stream with long throw. It uses a shaped nozzle to project supply air across large distances, then relies on induction to mix that air with room air before it reaches the occupied zone.

What is the difference between a jet nozzle and a jet diffuser?

“Jet nozzle” usually refers to the shaped outlet that creates the jet, often as a compact, directional device. “Jet diffuser” can describe a complete assembly that includes the nozzle, mounting frame, and sometimes a plenum box. In practice, people often use the terms interchangeably on HVAC projects.

What is a nozzle diffuser?

A nozzle diffuser combines nozzle behavior and diffuser function. It narrows the air path to create a controlled jet while still distributing air in a pattern suited to the space. The design manages both throw distance and mixing so conditions stay comfortable where people work or walk.

What is the purpose of a jet nozzle?

The purpose of a jet nozzle in ventilation is to send air over a long distance in a specific direction. It maintains velocity long enough for the jet to reach a remote zone, then allows induction and mixing to deliver usable airflow and temperature in that area.

What does a diffuser nozzle do?

A diffuser nozzle shapes and directs airflow from the duct into the room. It focuses the air into a jet, controls its spread, and supports mixing with the surrounding air. In tall or deep spaces, this control makes the difference between effective distribution and air that never reaches the occupied zone.

What are the 4 types of diffusers?

Many projects use ceiling diffusers, slot diffusers, linear bar grilles, and jet-type diffusers as four broad groups. Each type fits different ceiling heights, aesthetics, and throw requirements. Jet diffusers specialize in long-distance, directional supply rather than broad, low-velocity coverage.

What is the difference between a nozzle and a diffuser?

In fluid mechanics, a nozzle accelerates flow by reducing cross-sectional area, while a diffuser slows flow and recovers pressure by expanding it. In HVAC language, a jet nozzle diffuser blends both ideas: a nozzle-like outlet that accelerates air, wrapped in a diffuser assembly that distributes air into the space in a controlled way.

Can you put a diffuser attachment on any hair dryer?

Most hair dryers accept only attachments designed for that specific model or nozzle size. Using the wrong attachment can fit poorly, fall off, or change airflow in unintended ways. Hair styling devices and HVAC jet diffusers both rely on matched geometry to control air patterns effectively.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our portfolio includes jet nozzle diffusers, fans, dampers, smoke-control components, silencers, and precision-built aluminum ventilation parts engineered for high and complex spaces. By combining careful jet diffuser selection with robust system design, YAOAN VENTILATION helps projects achieve stable comfort, efficient AIRFLOW CONTROL, and reliable performance in atriums, factories, and large-volume halls.