Table of Contents

ToggleISO 9001 as the Framework Behind Everyday Decisions

When a project team orders a fan, damper, or acoustic component, they care about delivery dates and performance data. Behind those visible results, ISO 9001 gives YAOAN VENTILATION a structured way to make thousands of small decisions the same way every time.

Instead of relying on individual habits, the ISO 9001 Quality Management System (QMS) sets out:

- How we plan and review projects

- How we control design, production, and testing

- How we handle nonconformities and improve processes

That structure helps keep products and services consistent whether the project is a small plant upgrade or a long tunnel ventilation contract.

What ISO 9001 Means Inside a Ventilation Manufacturer

ISO 9001 does not replace engineering standards; it organizes how a company applies them. In an HVAC and FIRE SAFETY context, the QMS touches every step from enquiry to after-sales support.

From enquiry to contract review

- Technical and commercial requirements go through a defined review.

- Conflicts or unclear points trigger formal clarifications.

- Risks related to performance, schedule, and compliance are recorded and addressed.

This process reduces surprises later in design or production.

Design and development of products and solutions

For engineered items such as smoke-control fans or complex duct systems, the QMS requires:

- Documented design inputs, including codes and customer specifications

- Verification of calculations and selections

- Validation where products must meet specific performance, acoustic, or temperature targets

Design records then link directly to drawings, coordination models, and Factory Acceptance Tests.

Purchasing and supplier control

ISO 9001 also governs which suppliers YAOAN VENTILATION works with:

- Approved supplier lists based on capability and performance history

- Incoming inspections and verification of critical materials

- Corrective actions when supplied items do not meet agreed criteria

Controlled purchasing ensures that materials and components support long-term AIRFLOW CONTROL and FIRE SAFETY performance.

Production, inspection, and testing

On the factory floor, the QMS defines:

- Work instructions for fabrication, assembly, and finishing

- In-process checks at critical points (dimensions, balance, leakage, welding)

- Final inspections and testing documentation before release

Each unit leaves the factory with traceable records, which later support commissioning, troubleshooting, and O&M manuals.

Handling nonconformities and improvement

If an issue appears—internally or on a project site—ISO 9001 requires structured handling:

- Record the nonconformity with facts and evidence

- Contain the issue to protect current projects

- Identify root causes and implement corrective actions

- Verify that changes prevent recurrence

That cycle drives gradual improvement of both products and processes instead of one-time fixes.

How ISO 9001 Supports Project Stakeholders

For owners and operators

Owners gain confidence that:

- Products match the approved material submittals and performance claims

- Documentation such as FAT reports and O&M manuals follows a consistent format

- Problems trigger formal investigation and resolution, not ad-hoc reactions

This stability matters for long service life, audits, and insurance reviews.

For consultants and designers

Consultants work more efficiently with a manufacturer that:

- Uses consistent data sheets and submittal structures

- Provides traceable test reports and certifications

- Responds to technical queries through defined channels

ISO 9001 reinforces that discipline so coordination and approvals move faster.

For contractors and installers

Site teams benefit when:

- Deliveries match packing lists and approved references

- Labels, nameplates, and documentation align with drawings and BIM models

- Technical support follows an established escalation path

These outcomes reduce rework and simplify commissioning, especially on complex ventilation and smoke-control systems.

ISO 9001 in the Life of a Ventilation Product

A single fan or damper passes through multiple controlled stages under the QMS.

- Design and selection – Engineers apply defined design rules and checklists.

- Material control – Components come from approved sources with documented properties.

- Manufacturing – Operators follow work instructions; supervisors record key measurements.

- Testing – Performance, balance, leakage, and safety functions undergo defined checks.

- Identification – Nameplates and tags link each product to drawings and records.

- Delivery – Packing, transport, and storage conditions follow agreed requirements.

- After-sales – Feedback and field data feed into the improvement loop.

ISO 9001 connects these steps into a single documented system that auditors and customers can review.

FAQ

What is ISO 9001 for quality management?

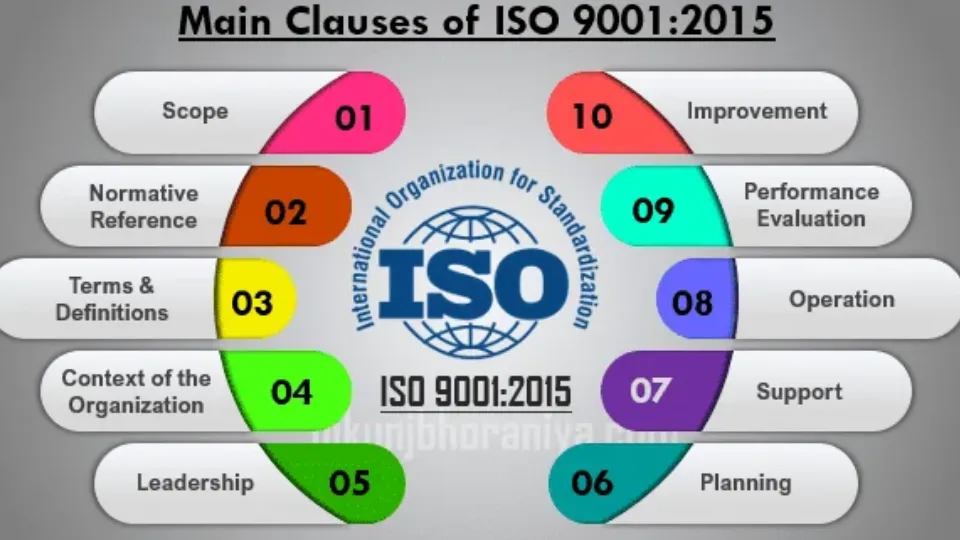

ISO 9001 is an international standard that defines requirements for a Quality Management System. It focuses on consistent processes, documented controls, and continual improvement so organizations can deliver products and services that meet customer and regulatory requirements.

What is the basic concept of ISO 9001?

The basic concept of ISO 9001 is that quality comes from controlled processes, not random inspection. It emphasizes understanding customer needs, managing risks, defining responsibilities, documenting key activities, and using data to improve performance over time.

What is QMS in simple terms?

A Quality Management System, or QMS, is the set of policies, procedures, and records a company uses to manage how it works. In simple terms, it is an agreed way of doing things that everyone follows so results stay consistent and traceable.

Why is ISO 9001 important?

ISO 9001 matters because it gives customers confidence that a company manages its work in a structured, auditable way. For ventilation and FIRE SAFETY products, that means more reliable performance, clearer documentation, fewer errors, and a stronger foundation for long-term support.

What are the 7 principles of ISO 9001?

Common summaries of ISO 9001 highlight seven quality management principles: customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management. These principles guide how the standard structures requirements.

What are the 6 documents required by ISO 9001?

The standard calls for several key documented elements, including a quality policy, quality objectives, a scope statement, documented processes where needed, and records that show planning and results. Exact “six documents” lists can vary, but the goal stays the same: define how the system works and prove that it runs as intended.

What is the main goal of ISO?

The main goal of ISO (the International Organization for Standardization) is to publish standards that support safety, reliability, and compatibility across products and services worldwide. ISO 9001 is one of those standards, focused specifically on quality management systems.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our ISO 9001–certified Quality Management System covers design, procurement, manufacturing, testing, and after-sales support for fans, dampers, smoke-control components, silencers, and precision-built aluminum ventilation parts. By strictly applying this system, YAOAN VENTILATION helps projects achieve stable performance, traceable compliance, and dependable support throughout the full life cycle of each installation.