Table of Contents

ToggleThe Impeller at the Center of Fan Performance

Every centrifugal fan starts with one critical decision: the impeller. Blade shape, balance, and material decide how much air the fan moves, how efficiently it runs, and how long it survives under heat and dust.

For HVAC and smoke-control systems, a correct impeller choice turns motor power into stable AIRFLOW CONTROL instead of vibration, noise, or premature failure.

Main Centrifugal Impeller Types in HVAC Fans

Different projects demand different pressure, efficiency, and dirt-handling capability. That is why engineers rely on three core centrifugal impeller families.

Forward-curved impellers

Forward-curved blades bend in the direction of rotation. They typically:

- Deliver relatively high airflow at lower pressures

- Run at lower tip speeds, which can help with noise in light-duty systems

- Suit small air handlers, cabinet fans, and residential or light commercial units

Their characteristic curve rises steeply and then drops, so selection must avoid unstable regions. For heavy industrial or smoke-control duties, other blade types usually work better.

Backward-curved and backward-inclined impellers

Backward-curved blades lean opposite the direction of rotation. These impellers:

- Offer higher efficiency over a broad working range

- Handle higher pressures at reasonable speeds

- Tend to be non-overloading on power, which simplifies motor sizing

Backward-inclined variants include airfoil and flat-plate designs. They are common in commercial and industrial HVAC plants where energy and reliability matter.

Radial (straight-blade) impellers

Radial impellers push air outward using straight or near-straight blades. They typically:

- Tolerate dust, fibers, and particulate better than airfoil shapes

- Produce higher pressure for a given size

- Run with greater mechanical robustness but lower efficiency than optimized backward-curved designs

You often see them in industrial exhaust, kitchen extraction, and areas where dirt or wear presents more risk than energy consumption.

Balance Grades and Vibration Control

Even a perfectly selected blade profile will fail early if it runs out of balance. Unbalance turns rotation into cyclic forces that damage bearings, foundations, and ductwork over time.

What balance grade means

Dynamic balancing standards (commonly expressed as grades such as G6.3 or G2.5) define acceptable residual unbalance for rotating parts. Lower grade numbers mean tighter balance. For HVAC fans:

- General-duty units commonly use grades around G6.3.

- High-speed or critical fans may use G2.5 or better.

The chosen grade must match speed, size, and structural stiffness so vibration remains within target limits across the speed range.

Balancing as part of quality and maintenance

Good practice includes:

- Balancing impellers at the factory on dedicated machines

- Re-balancing after blade repair, corrosion removal, or major deposits are cleaned

- Checking vibration during commissioning and periodically in service

Stable vibration protects bearings and keeps noise at predictable levels, which supports both comfort and FIRE SAFETY readiness.

Impeller Materials, Coatings, and Duty Conditions

Impellers see continuous stress: centrifugal forces, pressure differences, dirt impact, and sometimes high temperature. Material choice must reflect that environment.

Common materials

Typical options include:

- Carbon steel for general HVAC duties

- Galvanized or coated steel for standard corrosion protection

- Aluminum for reduced weight and specific corrosion conditions

- Stainless steel for aggressive, humid, or high-temperature environments

Each material brings its own limits on temperature, fatigue, and corrosion resistance.

Coatings and surface treatment

Coatings add protection where the base material alone is not enough:

- Epoxy or polyester coatings for mild corrosion environments

- Special high-temperature coatings for smoke-control and tunnel fans

- Smooth finishes that reduce dust adherence and ease cleaning

Consistent material and coating selection helps impellers maintain performance throughout their design life instead of losing efficiency as blades erode or corrode.

How Impeller Design Shapes Fan Performance

Small geometric changes on an impeller can have large effects on fan behavior.

- Blade angle and curvature influence the relationship between airflow, pressure, and power.

- Blade count and spacing affect noise spectrum and stall behavior.

- Shroud design and inlet cone geometry impact losses and efficiency.

By matching impeller design to system resistance and operating envelope, engineers position the fan on a stable, efficient part of its curve. That match reduces risk of overload, surge, and unexpected airflow shortfall when filters clog or dampers reposition.

Selection and Maintenance Considerations for Impellers

During selection and design

When YAOAN VENTILATION or a design team selects an impeller, they should confirm:

- Required airflow and pressure across realistic operating conditions

- Expected contamination level and cleaning strategy

- Temperature envelope, including smoke or emergency duty if relevant

- Balance grade and material consistent with speed and environment

In many projects, the fan manufacturer’s standard impeller range already covers these needs. Complex or safety-critical systems may require more detailed review.

During operation and service

In service, several inspection points protect impeller health:

- Regular vibration and noise checks

- Visual inspections for cracks, corrosion, or deformation during scheduled shutdowns

- Cleaning of deposits that change mass distribution or blade shape

- Verification that any repair work includes re-balancing

Documentation in O&M manuals should record impeller type, material, balance grade, and any special duty conditions so replacement and repair decisions stay aligned with the original design intent.

FAQ

What is an impeller used for?

An impeller is the rotating component that adds energy to a fluid. In fans and pumps, it converts shaft power into airflow or liquid flow by accelerating the medium outward or along the blades, creating the pressure difference that moves the fluid through ducts or piping.

What is a pump impeller?

A pump impeller is the blade assembly inside a centrifugal pump that spins with the shaft. As it rotates, it draws liquid into the center and throws it outward through the casing, increasing fluid pressure and directing flow to the discharge connection.

What is better, an impeller or agitator?

Impellers and agitators serve different roles. An impeller in a pump or fan moves fluid from one place to another. An agitator primarily mixes fluid in a tank or vessel. Which is “better” depends on whether the main need is transport, mixing, or both in a specific process.

Which impeller is more efficient?

Backward-curved or airfoil-style centrifugal impellers often achieve higher efficiency for many HVAC duties, especially at moderate to high pressures. However, their efficiency advantage must be weighed against contamination, wear, and specific system requirements that may favor simpler radial designs.

Can an impeller be repaired?

Many impellers can be repaired if damage remains within defined limits. Repairs may include weld buildup, crack removal, or replacement of sections, followed by machining and dynamic balancing. Any repair must respect material properties, geometry, and balance requirements to avoid creating new reliability risks.

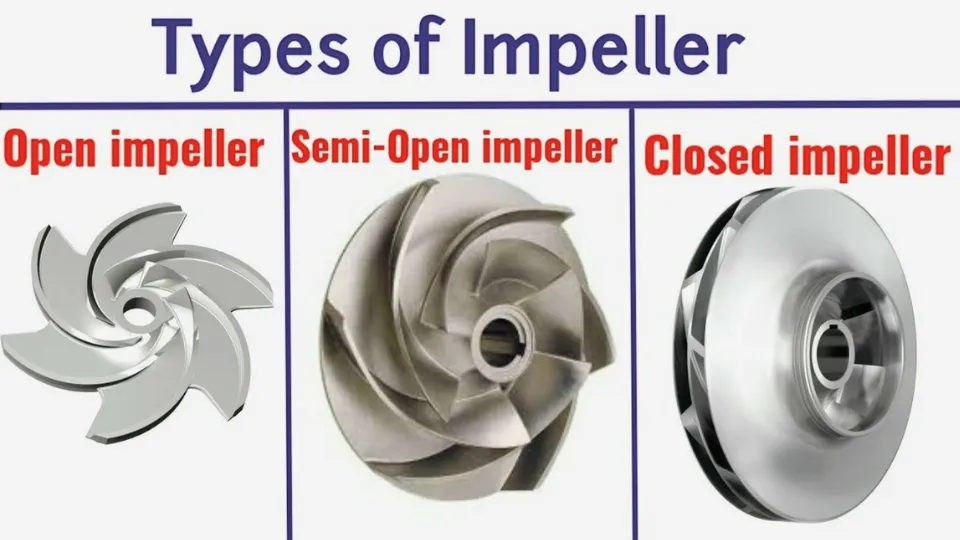

What are the three types of impellers?

In HVAC and many centrifugal applications, people often refer to forward-curved, backward-curved (or backward-inclined), and radial impellers as three main types. Each offers different combinations of efficiency, pressure capability, dirt tolerance, and acoustic behavior.

What is the lifespan of an impeller?

Impeller lifespan depends on speed, load, material, environment, and maintenance quality. In clean, moderate-duty HVAC service, impellers can operate for many years. In abrasive, corrosive, or high-temperature environments, life may shorten, and planned inspection and replacement become part of normal maintenance strategy.

What are the disadvantages of impeller pumps?

Centrifugal impeller pumps can lose performance when they handle high-viscosity fluids, operate far from their design point, or run dry. They may also suffer from erosion and cavitation in harsh conditions. Choosing the correct impeller style and controlling operating conditions reduce these disadvantages.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our fan designs use carefully selected impeller types, balance grades, and materials to match each project’s pressure, noise, temperature, and contamination demands. By treating the impeller as a critical engineering component—not just a spare part—YAOAN VENTILATION helps projects achieve stable AIRFLOW CONTROL, predictable performance, and long-term reliability in both comfort and FIRE SAFETY applications.