Table of Contents

ToggleBrake Horsepower in the World of Fans

When engineers size a fan, they do more than match airflow and pressure. They also calculate brake horsepower (BHP) so the motor can deliver enough mechanical power at the fan shaft, with margin for real operating conditions.

If BHP sits too low, the fan risks overload during peak duty. If it sits too high without control, the system wastes energy. Understanding BHP helps project teams choose motors and drives that keep AIRFLOW CONTROL stable and efficient.

What Brake Horsepower Actually Describes

Brake horsepower describes the mechanical power available at the rotating shaft. In fan work, that shaft usually belongs to the fan or its drive, not the motor terminals.

Engineers focus on BHP because it:

- Reflects real load after aerodynamic and mechanical losses in the fan

- Connects fan performance to motor duty and efficiency

- Changes as flow and pressure move along the fan curve

You can think of BHP as “how hard the fan pulls on the shaft” at a given operating point.

BHP, airflow, and pressure

For a given fan and air density, BHP increases when either:

- Airflow rises

- Static or total pressure rises

This relationship explains why changes to dampers, filters, or ductwork can push a fan toward higher BHP and potential motor overload, even if the motor rating did not change.

BHP, Motor kW, and Nameplate Ratings

From BHP to motor power

Fan calculations often give BHP, while motors use kilowatts (kW) on the nameplate. To connect them, engineers:

- Convert BHP to kW (1 HP ≈ 0.746 kW)

- Account for motor efficiency and drive losses

- Add a safety margin to cover uncertainty and future resistance increases

The required motor rating therefore sits above the fan BHP, not equal to it.

Why motor efficiency matters

Motor efficiency defines how much electrical power turns into shaft power. For the same BHP:

- A higher efficiency motor draws less electrical power

- A lower efficiency motor draws more power and runs hotter

On large ventilation systems, the combination of BHP, motor efficiency, and control method (across-the-line starter or VFD) drives long-term energy cost and thermal performance.

BHP in Fan Selection and Fan Curves

Reading fan curves with BHP in mind

Fan performance curves show airflow versus pressure, often with BHP lines. When selecting a duty point, designers:

- Locate the required airflow and pressure on the curve

- Read the BHP at that point

- Check that the operating point sits in a stable, efficient region

If later changes shift the operating point along the curve, BHP can increase or decrease, so understanding the shape of the curve matters.

Safety factors and real-world margins

Fans never operate in perfect laboratory conditions. Engineers add margin above calculated BHP to account for:

- Ductwork resistance higher than expected

- Dirty filters and fouled coils over time

- Density changes due to temperature or altitude

A common approach sets the motor rating some percentage above the maximum expected BHP, then confirms that overload protection and VFD parameters align with that choice.

Practical Considerations for BHP in Ventilation Systems

Coordination between disciplines

Good BHP decisions require communication between:

- Mechanical designers, who calculate airflow and pressure

- Electrical teams, who size motors, starters, and cables

- Controls engineers, who define speed control and overload settings

YAOAN VENTILATION equipment data supports this coordination by presenting BHP, efficiency, and duty points clearly on submittals and fan schedules.

Fire and smoke-control duties

Smoke-control or high-temperature fans often run at demanding conditions during rare events. Their BHP under smoke duty can differ from comfort-duty values.

Designers check that:

- Motor size and insulation support both temperature and BHP requirements

- Drives and supplies can deliver that power under emergency conditions

- Protection settings do not trip the fan prematurely during a real event

This link between BHP and FIRE SAFETY duty forms a critical part of system design.

FAQ

What is brake horsepower BHP?

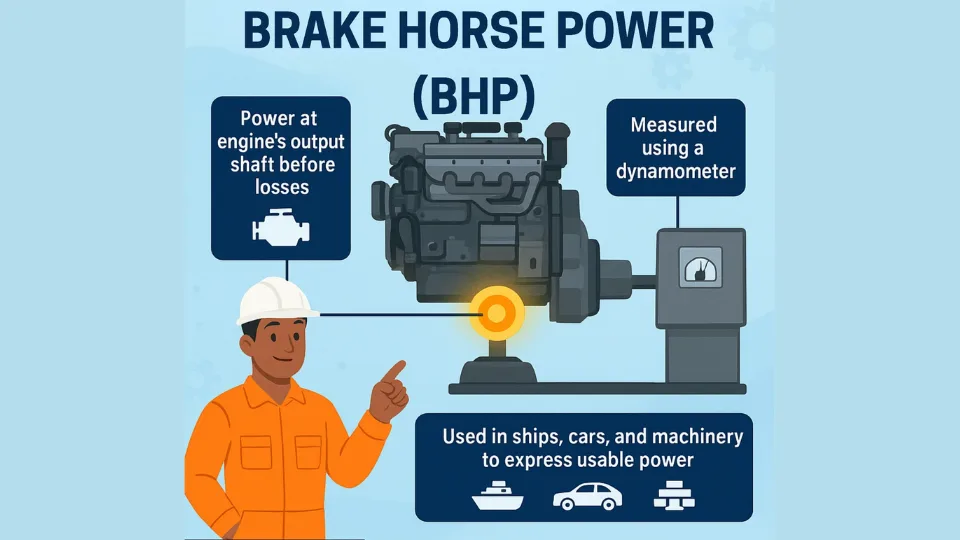

Brake horsepower (BHP) is the mechanical power available at a rotating shaft before transmission or electrical losses. In fan applications, it describes how much power the fan actually needs at its shaft to deliver the required airflow and pressure, under specified air density conditions.

What does BHP stand for?

BHP stands for brake horsepower. The word “brake” comes from early methods of measuring shaft power using dynamometers, where a braking device applied load to the rotating shaft while engineers measured torque and speed.

What is HP and BHP?

Horsepower (HP) generally refers to power, either mechanical or engine-rated, while brake horsepower (BHP) refers specifically to mechanical power at the shaft after internal losses. In fan and motor work, BHP describes load at the shaft; HP or kW on the motor nameplate describes available electrical-to-mechanical power capacity.

What is the brake horsepower?

Brake horsepower is the shaft power that a machine delivers or requires, measured under load with a brake or dynamometer. For a fan, it represents the power necessary to overcome aerodynamic resistance and move air at the specified duty point.

Is 300 HP equal to 300 horses?

“Horsepower” uses a historical comparison with draft horses, but 300 HP does not literally equal 300 horses. It means the machine can deliver power equivalent to 300 times the defined unit of one horsepower, which is a standardized rate of work, not a count of animals.

What is 400hp in BHP?

In many automotive contexts, people treat quoted HP and BHP figures similarly, although definitions can vary between brake, wheel, or metric horsepower. In engineering calculations for fans and motors, you convert between HP and kW, then consider BHP as the shaft requirement and motor HP as the available capacity above that requirement.

What car has the highest BHP ever?

Ultra-high-performance cars from specialized manufacturers claim extremely high BHP figures, and the exact “highest” value changes as new models appear. These automotive records do not affect fan or HVAC design, where BHP focuses on reliable, continuous-duty mechanical power rather than peak performance.

How many horsepower is a 500 cc engine?

A 500 cc engine’s horsepower depends on its design, speed, and tuning. Some small-displacement engines produce modest HP for durability and efficiency, while high-performance versions produce much more power per cc. Engine displacement alone does not set BHP; detailed engine design and operating conditions decide the final figure.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our fan selections and technical documentation present airflow, pressure, and BHP clearly so designers can size motors, drives, and power supplies with confidence. By combining accurate brake horsepower data with robust mechanical design, YAOAN VENTILATION helps projects achieve reliable AIRFLOW CONTROL, safe FIRE SAFETY operation, and efficient energy use throughout each system’s service life.