Table of Contents

ToggleInvisible Dust, Real Engineering Problem

Walk into any lobby, workshop, or server room and the air already carries a mix of invisible particles. Some came from traffic outside, some from prints, fabrics, people, and some from the systems meant to control the air in the first place.

For HVAC designers and facility teams, airborne particles are not an abstract environmental topic. They influence filter loading, coil performance, indoor air quality, and even how long equipment runs before cleaning or failure.

What Lives in the Air of a Typical Building

Instead of starting with size charts, it helps to picture the real mix moving through a supply duct.

Categories you actually encounter

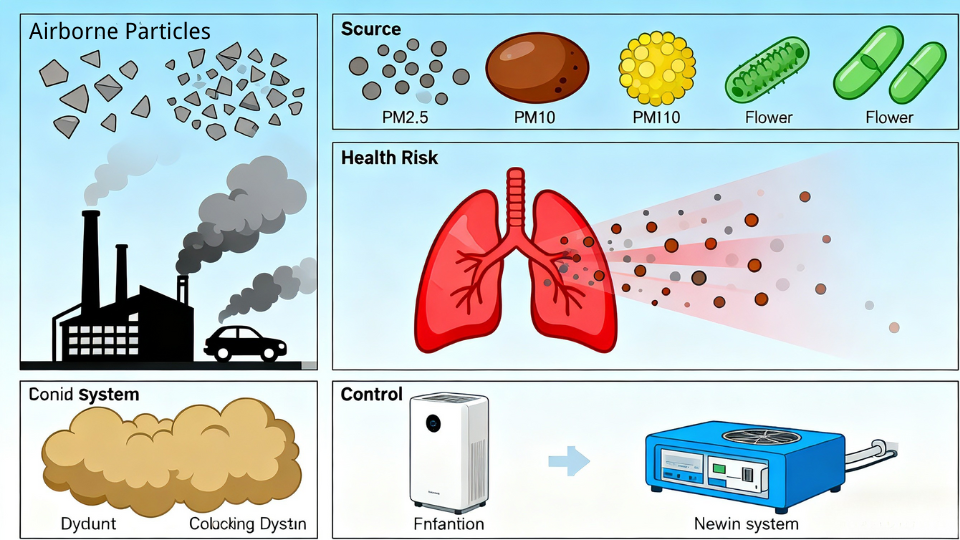

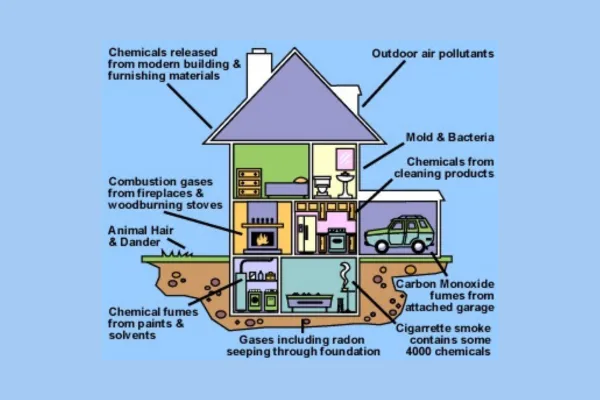

Most commercial buildings see four broad particle categories:

- Outdoor pollution that comes in with ventilation air

Road dust, PM2.5 from vehicles, industrial emissions, seasonal haze. - Indoor “people” and material particles

Skin flakes, hair, textile fibers, paper dust from printers and packaging. - Process and activity particles

Cooking aerosols, welding fume in workshops, sanding dust in maintenance areas. - Biological particles

Pollen, mold spores, fragments of microorganisms, and droplets that can carry pathogens.

Each group behaves differently, settles at different rates, and responds differently to filtration and ventilation.

Why particle size still matters

Once you know the sources, size tells you where control must be strongest:

- Larger particles (around 10 microns) irritate the upper airways and settle quickly on surfaces and coils.

- Fine particles (PM2.5 and below) stay suspended longer, penetrate deeper into the lungs, and load filters more aggressively.

- Ultrafine fractions ride air currents and can pass through low-grade filters almost unchanged.

HVAC control strategies must assume that not all particles behave like “dust” on a desktop.

How Particles Move Through a Ventilation System

The journey from intake to occupied zone

A simple path helps illustrate the problem:

- Outdoor air enters through louvers and intake plenums carrying local pollution.

- Part of that load hits the first filter bank, where coarse filters knock back larger dust and debris.

- Remaining particles travel across coils, through fans, and into ductwork.

- Internal surfaces collect some fraction; the rest travels into rooms and corridors.

- Indoor sources add their own load before air returns to the system or exhausts.

Every link in that chain offers an opportunity to control particles—or to generate new ones if maintenance falls behind.

Interaction with airflow patterns

Particles follow air, but never perfectly:

- Dead zones and short-circuiting let dirty air linger near occupants.

- High velocities in the wrong place re-suspend settled dust and push it into supply streams.

- Pressure imbalances pull particles from “dirty” rooms into “cleaner” zones such as offices or patient areas.

This is why AIRFLOW CONTROL and filtration always belong in the same conversation.

Designing Ventilation Around Particle Control

Different buildings need different levels of control. A basic office, a laboratory, and a surgery suite do not share the same targets. Still, the decision sequence often looks similar.

Step 1: Define the risk level and dominant sources

Questions to answer early:

- Are outdoor particles or indoor activities the main concern?

- Are there vulnerable occupants (children, elderly, patients, clean manufacturing)?

- Are there regulatory or certification targets for particulate levels?

Those answers determine whether standard MERV filters and good housekeeping are enough, or whether the design must include high-efficiency filtration and stricter zoning.

Step 2: Choose the filter train and locations

A robust strategy usually combines stages rather than one “hero” filter:

- Prefilter stage near the intake to trap larger dust and protect downstream equipment.

- Fine filter stage to capture PM2.5 and smaller fractions at the air-handling unit.

- Local filters in fan coils or terminals where zones need extra protection or where coils are hard to clean.

Each stage must match available fan pressure and maintenance capacity. Over-specifying filters without checking fan curves or staffing only moves the problem downstream.

Step 3: Use zoning and pressure to limit particle spread

Once filtration is in place, zoning finishes the picture:

- Keep cleaner zones (offices, labs, patient areas) at slightly higher pressure than surrounding corridors or service rooms.

- Keep high-particle spaces (workshops, copy rooms, kitchens) slightly negative relative to adjacent areas.

- Route exhaust from high-load rooms directly outdoors, not back through shared plenums.

Good pressure zoning prevents one local source from becoming a building-wide particle generator.

Operating Practices that Make or Break Particle Control

Even the best design fails if daily operation and maintenance drift away from the original assumptions.

Filter and coil care

Practical habits that protect performance:

- Change filters based on differential pressure or program, not only on visual inspection.

- Clean or treat coils and drain pans so they do not become particle sources or support growth.

- Inspect duct interiors periodically in high-load buildings, especially near intakes and mixing sections.

These actions preserve both indoor air quality and system efficiency.

Housekeeping and source control

Ventilation cannot solve every particle problem alone. Simple measures help:

- Use local capture (hoods, snorkels) where work creates visible dust or fumes.

- Control moisture to reduce mold and other biological particles.

- Keep mechanical rooms and intake areas clean so systems do not re-circulate deposits.

When building operations pay attention to both sources and systems, particle levels stabilize instead of drifting upward over time.

FAQ

What is the meaning of airborne particles?

Airborne particles are tiny solid or liquid materials that can stay suspended in air for a period of time. They range from coarse dust and pollen to fine combustion residues and microscopic droplets, and they move wherever the air from ventilation and drafts carries them.

Is dust an airborne particle?

Yes. Dust becomes an airborne particle load whenever activities disturb settled material on floors, shelves, or ducts. Once in the air, dust can reach breathing zones, enter HVAC systems, and collect on filters and coils until filtration and cleaning remove it.

What are airborne particulate materials?

Airborne particulate materials include any small solids or droplets that air transports through a space. That group covers soil dust, smoke, soot, fibers, skin flakes, mold spores, and many types of aerosols produced by work processes or combustion.

What is another name for airborne particles?

Another common name is particulate matter, often shortened to PM. Technical and regulatory documents use labels such as PM10, PM2.5, or ultrafine particles to describe size ranges of this particulate matter.

What are the most harmful airborne particles?

Fine particles such as PM2.5 and many ultrafine particles typically raise the greatest concern because they can penetrate deep into the lungs and remain suspended for long periods. Their risk level depends on chemistry and exposure time, with combustion-related particles and certain industrial aerosols often at the top of priority lists.

How to remove airborne dust particles?

Buildings remove airborne dust through a combination of filtration, ventilation, and cleaning. Filters at air handlers capture particles each time air recirculates. Outdoor air dilutes indoor-generated dust. Regular housekeeping then removes settled material so it does not re-enter the air each time people move or equipment runs.

What are the 7 most common airborne diseases?

Lists vary, but many references highlight illnesses such as influenza, tuberculosis, measles, chickenpox, COVID-19, whooping cough, and some fungal or viral infections as common airborne or aerosol-transmitted diseases. Control strategies pair ventilation and filtration with vaccination, hygiene, and medical guidance from public health authorities.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our portfolio includes fans, dampers, smoke control components, silencers, and precision-built aluminum ventilation parts, all designed to integrate with filtration, zoning, and air-cleaning strategies. By combining robust equipment with engineered particle control, YAOAN VENTILATION helps projects protect occupant health, stabilize indoor air quality, and maintain code-compliant performance across the full system life cycle.