Table of Contents

Toggleir Shafts in the Vertical Breathing System of a Building

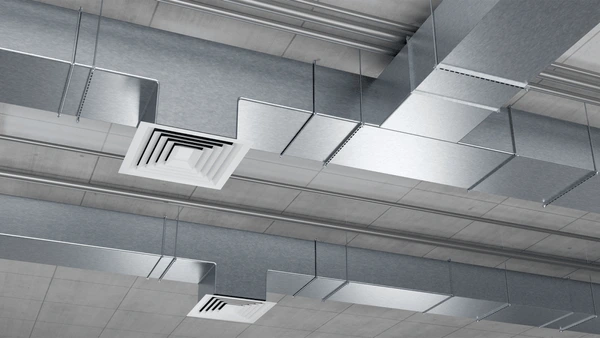

Every multi-story building needs a way to move air vertically. Duct risers handle most of that job, but the air shaft provides the protected route that allows those ducts, openings, and vents to move air between floors without compromising safety.

An air shaft acts as a dedicated vertical zone. It keeps ventilation paths organized, separates them from occupied spaces, and supports long-term inspection and maintenance. In many projects, the quality of the shaft design decides how stable and maintainable the entire ventilation system feels over time.

Functions of an Air Shaft in Ventilation Strategy

Moving air where horizontal paths fall short

Air shafts enable:

- Fresh air distribution from central intakes to upper floors

- Exhaust removal from bathrooms, kitchens, and internal rooms

- Relief and pressure-equalizing paths in tall buildings

Instead of scattering ducts randomly through structure, the design channels most vertical routes through these defined shafts. That approach supports cleaner coordination, easier routing, and more predictable AIRFLOW CONTROL.

Supporting natural and mechanical ventilation

Some shafts serve purely mechanical systems. Others support both natural and mechanical flows. Typical uses include:

- Stack-assisted exhaust, where warm air rises and leaves at the top

- Combined operation with fans to guarantee minimum flow rates

- Integration with smoke exhaust systems in defined scenarios

The designer chooses the configuration based on climate, building height, and code requirements.

Design Considerations and Norms for Air Shafts

Geometry, routing, and service density

An effective air shaft design does more than reserve space. It defines:

- Shaft cross-sectional area for current and future duct loads

- Clear separation between supply, return, and exhaust routes

- Limits on how many systems can share one shaft without conflict

Adequate space prevents ducts from crowding each other or blocking access to dampers and inspection points. A shaft that is too small at design stage becomes a permanent constraint for the building.

Access and maintainability

Maintenance and inspection need direct, safe access. In practice, that means:

- Access doors at damper locations and key junctions

- Clear work platforms or landings near openings

- Coordination with finishes so doors remain visible and reachable

These details allow teams to test fire and smoke dampers, inspect duct seals, and check for damage without cutting new openings later.

Acoustic and comfort performance

Air shafts sit close to occupied rooms in many floor layouts. Designers address:

- Sound transmission from fans and ducts through shaft walls

- Flanking noise paths around penetrations

- Vibration control where ducts and fans connect to structure

The shaft design becomes part of the building’s overall acoustic strategy.

Construction Requirements and Quality Control

Building the shaft correctly

During construction, the air shaft moves from a line on drawings to a structural element. Quality checks focus on:

- Correct wall type and thickness for fire and acoustic ratings

- Smooth internal surfaces where required for airflow and cleaning

- Proper alignment so duct runs and openings match coordinated models

Supervisors confirm that penetrations occur only where drawings and fire details allow them. Unplanned openings can compromise both performance and FIRE SAFETY.

Penetrations, supports, and sealing

Every duct, cable tray, or pipe that passes through an air shaft wall needs controlled detailing:

- Proper sleeves and firestopping at each penetration

- Independent supports for ducts so loads do not damage the shaft wall

- Airtight sealing where leaks would disturb pressure control or airflow

These construction details decide how well the shaft supports pressure zoning, smoke control, and energy efficiency.

Fire Separation and Life Safety in Air Shafts

Keeping fire and smoke from using the shaft as a chimney

An air shaft can act as a vertical chimney if design and construction do not control it. For that reason, codes treat shafts as critical life-safety elements. Key measures include:

- Shaft walls with defined fire-resistance ratings

- Fire dampers or combination fire-smoke dampers at duct penetrations where required

- Limited and protected openings between shaft and occupied spaces

The fire-safety concept treats the shaft as a protected route, not a shortcut for fire and smoke spread.

Coordinating with smoke control and pressurization

In some buildings, specific air shafts also serve smoke control functions. They may:

- Carry dedicated smoke exhaust ducts

- Work with stair pressurization systems

- Interact with mechanical fans that start in alarm conditions

Designers align damper operation, fan logic, and BAS monitoring so shafts support both daily ventilation and emergency conditions without conflict.

Operation, Inspection, and Long-Term Performance

Once the building enters service, air shafts become part of routine facility work. Teams benefit from:

- Periodic visual checks of shaft interiors where safe access exists

- Regular testing of dampers and actuators at shaft penetrations

- Inspection for water intrusion, corrosion, or debris accumulation

Documented inspections and clear as-built drawings help staff understand how each shaft interacts with supply, exhaust, and smoke-control systems across floors. That understanding protects both comfort and life safety throughout the building’s life cycle.

FAQ

How does an air shaft work?

An air shaft works as a vertical passage that carries ducts or openings between floors. Pressure differences from fans, wind, or stack effect drive air through connected inlets and outlets. The shaft keeps that vertical path organized, protected, and separated from occupied rooms.

What is the purpose of an air shaft?

The purpose of an air shaft is to provide a dedicated vertical route for ventilation and exhaust systems. It supports fresh air supply, removal of stale or polluted air, and in some cases smoke control. The shaft also allows designers to manage fire separation and maintenance access more effectively than scattered penetrations.

What is the purpose of a ventilation shaft?

A ventilation shaft focuses specifically on moving air for comfort and air quality. It can bring outdoor air to interior zones, remove exhaust from bathrooms or service rooms, or support natural stack-driven flow. Mechanical fans often connect to these shafts to guarantee minimum air change rates in all conditions.

Why do buildings have air shafts?

Buildings use air shafts to move air vertically without taking up excessive floor area or cutting random paths through structure. Shafts simplify coordination among trades, make it easier to maintain ducts and dampers, and help meet fire, acoustic, and ventilation codes. They become especially important in high-rise and deep-plan buildings.

Why did pyramids have air shafts?

In historical pyramids, narrow “air shafts” often served symbolic, astronomical, or ceremonial purposes rather than modern HVAC functions. They aligned with stars or specific directions and did not operate as full building ventilation systems. Today’s air shafts use similar geometry for a different, engineering-focused purpose.

What are the two types of shafts?

In building services discussions, people often distinguish between service shafts and ventilation shafts. Service shafts carry multiple utilities such as plumbing and electrical. Ventilation shafts focus on air movement for HVAC and smoke control. Some projects combine them, but careful fire and acoustic detailing then becomes essential.

How long can a person stay on a ventilator?

The time a person stays on a medical ventilator depends on their condition, treatment plan, and response to care. Some patients need support for hours or days, others for longer periods under close medical supervision. Questions about ventilator duration always require direct guidance from qualified healthcare professionals.

Do homes need ventilation shafts?

Many homes use simpler solutions such as direct duct runs, attic spaces, and wall vents instead of full vertical shafts. Taller residential buildings and dense urban projects often benefit from defined ventilation shafts to manage bathroom, kitchen, and general exhaust. The need depends on building height, layout, and local code requirements.

What are the 4 stages of ventilation?

When people discuss ventilation in a respiratory sense, they often think about four phases: drawing air into the lungs, gas exchange in the lungs, transporting gases in the bloodstream, and gas exchange at body tissues. In building design, the focus shifts to outdoor air intake, distribution, contaminant removal, and exhaust or relief.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our portfolio includes fans, fire dampers, smoke control components, silencers, and precision-built aluminum ventilation parts designed to integrate cleanly with shaft and riser designs. By combining reliable equipment with careful vertical AIRFLOW CONTROL planning, YAOAN VENTILATION helps projects achieve stable ventilation, robust FIRE SAFETY separation, and consistent long-term performance across every floor.