Table of Contents

ToggleIntroduction: Why Hospital HVAC Systems Are Mission-Critical

Hospitals and healthcare facilities impose some of the most stringent HVAC requirements of any building type. Unlike commercial offices or retail spaces, hospital HVAC systems must simultaneously address:

- Infection prevention and airborne pathogen control

- Precise temperature, humidity, and pressure zoning

- Continuous 24/7 operation with high reliability

- Compliance with healthcare regulations and standards

- Energy efficiency despite high air change rates

A well-designed hospital HVAC system directly impacts patient safety, clinical outcomes, staff productivity, and regulatory compliance.

Key HVAC Design Objectives in Healthcare Facilities

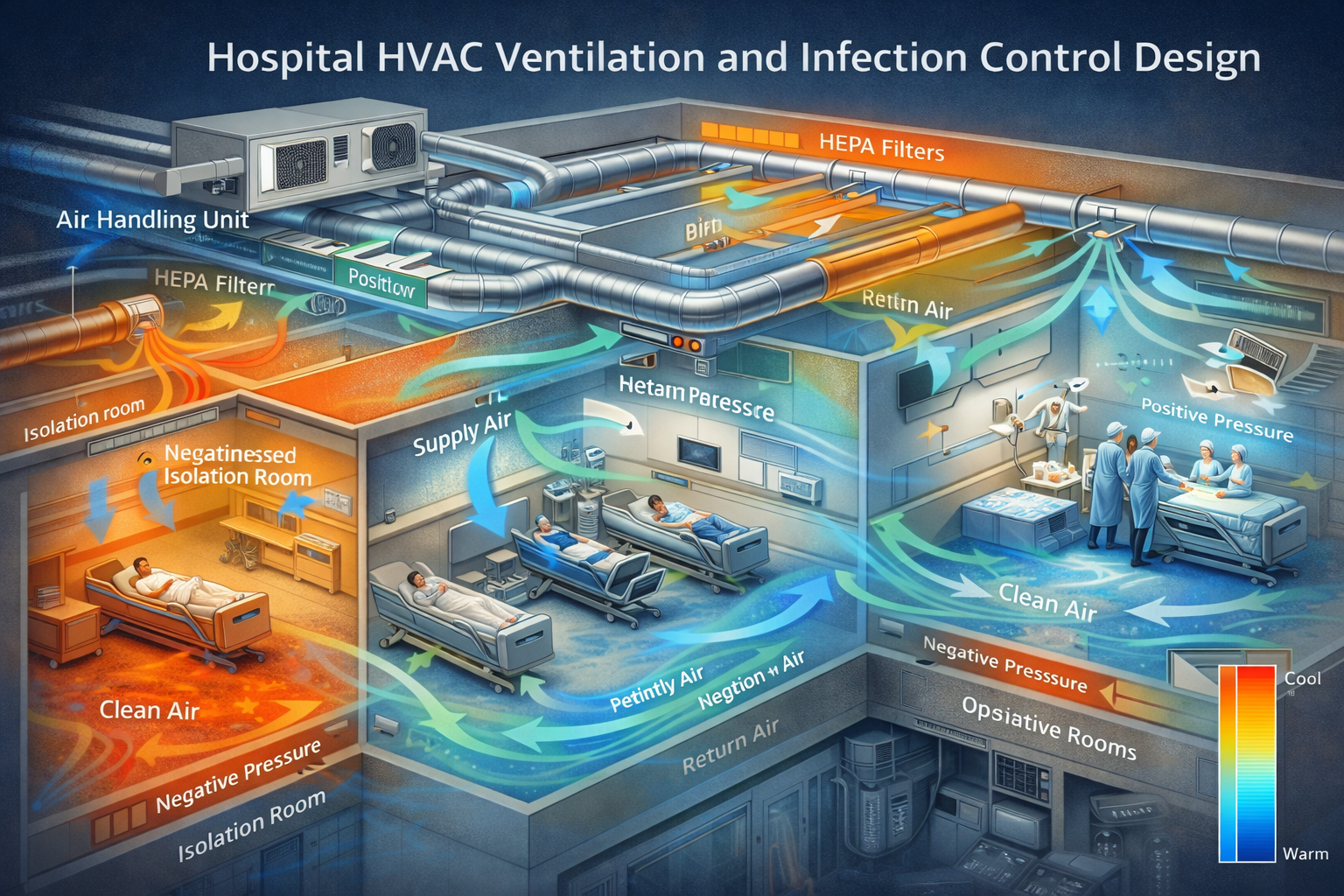

Infection Control and Airborne Contaminant Management

Healthcare HVAC systems are integral to infection prevention strategies. Design priorities include:

- High air change rates (ACH) in critical spaces

- Directional airflow control

- HEPA or high-efficiency filtration

- Segregation of clean and contaminated air streams

Critical zones such as operating rooms (ORs), isolation rooms, ICUs, and laboratories require controlled airflow patterns to minimize cross-contamination.

Thermal Comfort for Patients and Staff

Thermal comfort in hospitals is not uniform across spaces:

- Patient wards prioritize stable, draft-free conditions

- Operating rooms require cooler environments

- Pharmacies and laboratories demand tight temperature tolerances

HVAC zoning and advanced controls are essential to meet these diverse requirements without energy waste.

Core HVAC System Components for Hospitals

Ventilation Systems and Air Distribution Strategies

Hospital ventilation design typically incorporates:

- 100% outdoor air or high fresh-air ratios

- Variable Air Volume (VAV) systems with reheat

- Laminar airflow systems for operating theatres

- Displacement or low-turbulence ventilation in patient areas

Airflow distribution must be engineered to support pressure differentials, ensuring air always moves from clean to less-clean areas.

Filtration and Air Cleaning Technologies

Filtration is a cornerstone of healthcare HVAC design:

- Pre-filters for coarse particle removal

- MERV 13–16 filters in general healthcare zones

- HEPA filters in ORs, isolation rooms, and cleanrooms

Supplementary technologies may include:

- UVGI (Ultraviolet Germicidal Irradiation) in air-handling units

- In-duct or upper-room UV systems for pathogen reduction

Pressure Control and Zoning

Maintaining correct room pressurization is critical:

- Positive pressure: Operating rooms, clean corridors

- Negative pressure: Isolation rooms, soiled utility rooms

Pressure monitoring devices and automated dampers are typically integrated into the Building Management System (BMS) for real-time control.

Energy Efficiency in Hospital HVAC Systems

Balancing High ACH with Energy Performance

Hospitals consume significantly more energy than standard buildings due to high ventilation rates. Energy-saving strategies include:

- Heat recovery wheels or run-around coils

- High-efficiency chillers and boilers

- Demand-controlled ventilation in non-critical zones

- Variable-speed fans and pumps

Proper system integration can reduce operational costs without compromising clinical safety.

Smart Controls and Building Automation

Modern hospital HVAC systems rely on advanced automation:

- Continuous monitoring of temperature, humidity, and pressure

- Alarm systems for airflow or pressure deviations

- Integration with infection control protocols

Smart HVAC controls enhance reliability and enable predictive maintenance.

Compliance with Healthcare Standards and Codes

Hospital HVAC systems must align with international and regional standards, such as:

- ASHRAE 170 – Ventilation of Health Care Facilities

- HTM 03-01 (UK)

- DIN 1946 (Germany)

- Local healthcare authority regulations

Early coordination between HVAC engineers, architects, and medical planners is essential to ensure compliance and avoid costly redesigns.

Image Reference (for Blog Integration)

Image Alt Text

Hospital HVAC system airflow design showing pressure zoning, HEPA filtration, and air distribution in operating rooms

Image Title

HVAC Ventilation and Infection Control Design for Healthcare Facilities

Typical HVAC Challenges in Healthcare Projects

Retrofit vs New Construction

- Retrofit projects must work within existing shaft space and infrastructure

- Continuous operation limits shutdown windows

- Phased construction requires temporary HVAC solutions

Reliability and Redundancy

Hospitals require:

- N+1 redundancy for critical equipment

- Backup power integration

- Fail-safe control strategies

System resilience is as important as performance.

Conclusion: HVAC as a Clinical Infrastructure System

In healthcare facilities, HVAC systems are not merely comfort solutions—they are clinical infrastructure. A well-engineered hospital HVAC system:

- Reduces infection risks

- Ensures regulatory compliance

- Improves patient outcomes

- Controls long-term operational costs

For architects, engineers, and healthcare investors, early HVAC strategy alignment is critical to project success.

FAQ – HVAC Solutions for Hospitals and Healthcare Facilities

What type of HVAC system is best for hospitals?

Hospitals typically use centralized air-handling systems with high fresh-air ratios, HEPA filtration, and advanced pressure control, tailored to each clinical zone.

Why is pressure control important in healthcare HVAC design?

Pressure differentials prevent contaminated air from spreading into clean areas, reducing the risk of airborne infection transmission.

How is energy efficiency achieved in hospital HVAC systems?

Through heat recovery, high-efficiency equipment, smart controls, and optimized ventilation strategies in non-critical areas.

Are hospital HVAC systems required to operate 24/7?

Yes. Healthcare HVAC systems are designed for continuous operation with redundancy to ensure uninterrupted environmental control.