Table of Contents

ToggleIntroduction

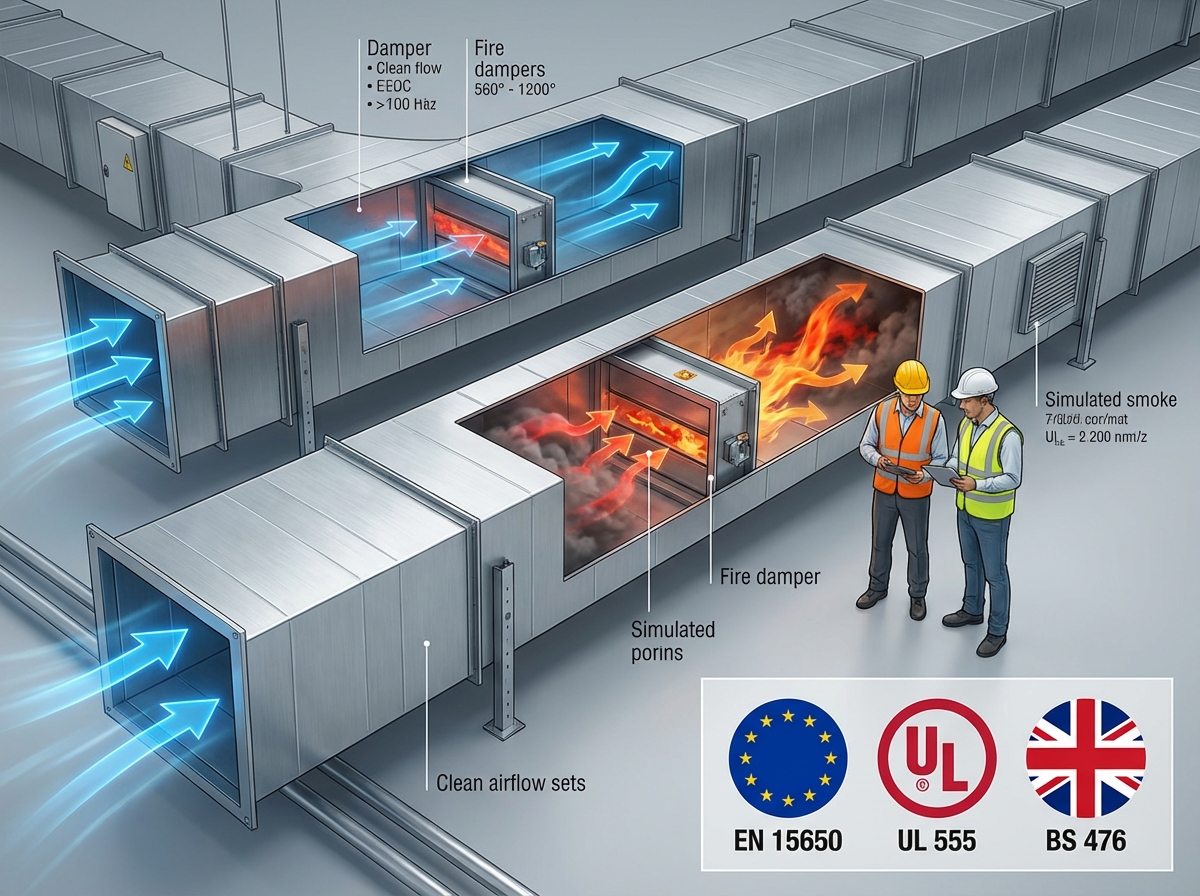

Fire dampers are essential HVAC components that prevent the spread of fire and smoke through ventilation systems. Compliance with international standards such as EN (Europe), UL (North America), and BS (British Standards) ensures:

- Safety of building occupants

- Regulatory approval and code compliance

- Reliable HVAC system performance

- Reduced risk of property damage and liability

YAOAN Ventilation provides fire dampers and solutions designed to meet these international standards, supporting safe and compliant HVAC systems worldwide.

Key Standards for Fire Dampers

EN Standards (European Norms)

Requirements:

- Fire and smoke dampers tested under EN 1366-2 / EN 15650

- European fire resistance classifications (E, EI)

- Integration with building ductwork, ceilings, and walls

Implementation Tips:

- Select EN-certified dampers for design and installation

- Verify manufacturer test reports and CE marking

- Ensure installation follows EN guidelines to maintain compliance

UL Standards (Underwriters Laboratories)

Requirements:

- UL 555 for fire dampers and UL 555S for smoke dampers

- Tested for high-temperature closure and operational reliability

- Common North American fire ratings (1h, 1.5h, 3h)

Implementation Tips:

- Use UL-listed dampers with documented test reports

- Perform installation and functional tests as per UL instructions

- Maintain records for Authorities Having Jurisdiction (AHJ) inspections

BS Standards (British Standards)

Requirements:

- BS 476 series for fire resistance of building materials and components

- Fire dampers must meet British testing protocols for temperature and smoke

- Often required in UK and Commonwealth countries

Implementation Tips:

- Select BS-certified dampers for UK projects

- Ensure proper installation in ducts, ceilings, and wall penetrations

- Conduct verification tests to confirm BS compliance

Best Practices for Fire Damper Compliance

Product Selection

- Identify applicable standard (EN, UL, BS) based on project location

- Choose dampers with appropriate fire ratings and airflow performance

Coordination and Installation

- Integrate dampers with HVAC, fire detection, and smoke control systems

- Use BIM or CFD modeling to validate airflow and safety performance

- Follow manufacturer and code-specific installation guidelines

Testing and Maintenance

- Perform factory and site acceptance testing (FAT/SAT)

- Schedule regular inspections and preventive maintenance

- Maintain detailed documentation for regulatory compliance and audits

FAQ

Why is compliance important for fire dampers?

Compliance ensures occupant safety, legal adherence, and reliable fire protection within HVAC systems.

What are the differences between EN, UL, and BS standards?

EN focuses on European fire classes and integration, UL emphasizes high-temperature closure and North American ratings, and BS specifies British fire testing protocols.

How often should fire dampers be tested?

At installation, after system modifications, and periodically as per relevant standards (typically annually).

Does YAOAN provide fire dampers compliant with multiple standards?

Yes, YAOAN offers EN-certified, UL-listed, and BS-compliant fire dampers for international projects.

About YAOAN Ventilation

YAOAN Ventilation delivers fire dampers and smoke control solutions compliant with EN, UL, and BS standards. Our product portfolio includes fire and smoke dampers, control systems, and integrated HVAC safety components. We ensure safety, regulatory compliance, and reliable performance in commercial buildings, industrial facilities, and infrastructure projects worldwide.