Table of Contents

ToggleIntroduction: The Choice Between Local and Imported Equipment

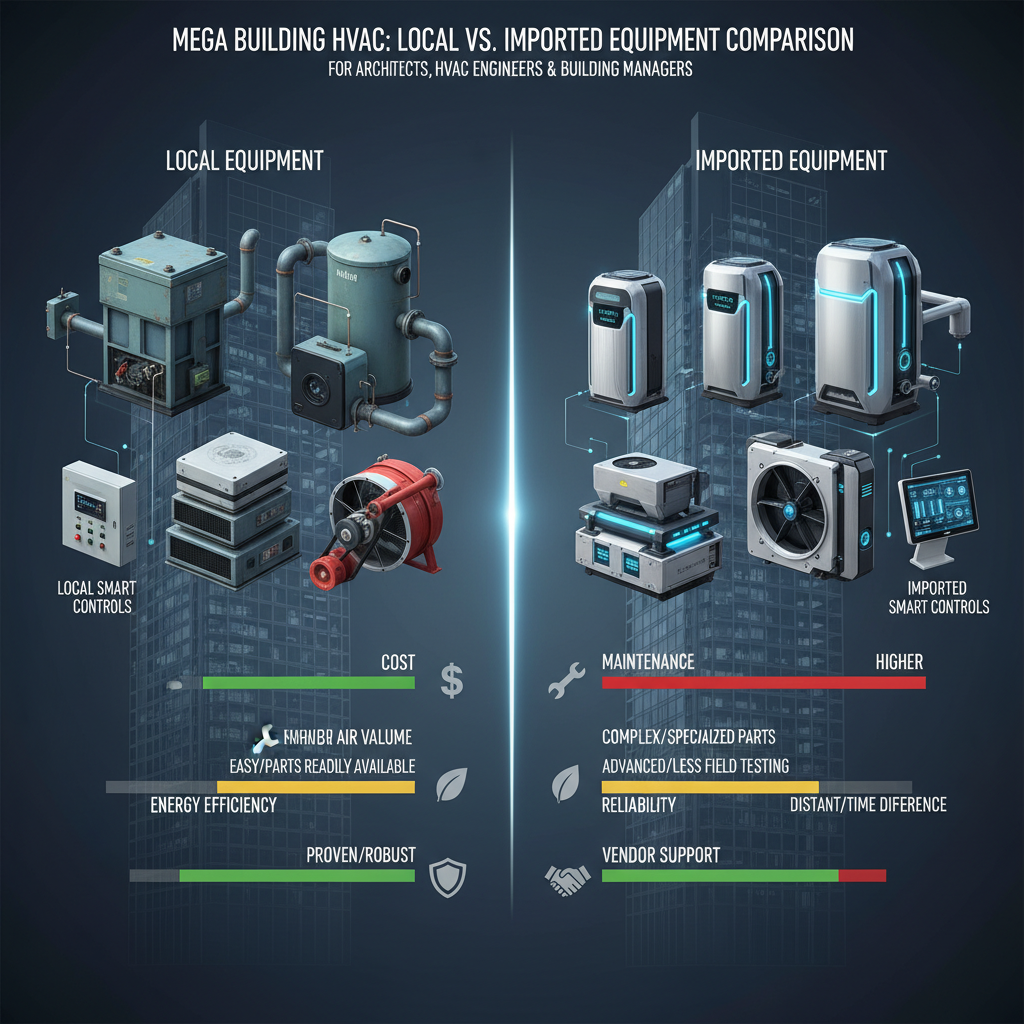

Selecting HVAC equipment for mega projects involves evaluating:

- Initial purchase cost

- Long-term performance and reliability

- Maintenance requirements

- Energy efficiency and compliance with standards

Both local and imported equipment have pros and cons that impact project budget, operation, and sustainability.

Key Comparison Factors

Cost and Budget Considerations

- Local equipment generally offers lower upfront costs and easier procurement

- Imported systems may have higher initial costs but advanced features

- Evaluate total cost of ownership (TCO), including installation, energy, and maintenance

Performance and Quality

- Imported systems may provide higher precision, better control, and longer warranties

- Local systems can meet regional climate requirements and support faster service response

- Check certifications (EN, UL, NFPA, ISO) to ensure compliance

Maintenance and Spare Parts

- Local equipment often benefits from shorter supply chains and faster parts availability

- Imported systems may require longer lead times and specialized technicians

- Factor training, service contracts, and maintenance costs into project planning

Energy Efficiency and Sustainability

- Imported systems may feature cutting-edge energy-saving technologies like VAV, ERV/HRV, or variable-speed drives

- Local manufacturers increasingly offer high-efficiency solutions tailored for regional energy codes

- Consider LEED or green building certification targets

Strategies for Making the Right Choice

Hybrid Approach

- Combine local and imported components for optimal performance and cost control

- Example: use local ductwork and fans, imported chillers and control systems

Lifecycle Planning

- Analyze system lifespan, maintenance schedules, and expected performance degradation

- Plan component replacement or upgrades based on TCO and project requirements

Vendor Support and Reliability

- Assess service network, training programs, and response time

- Ensure BMS compatibility, spare parts logistics, and technical support

Image Reference (for Blog Integration)

Image Alt Text:

Comparison diagram showing local vs imported HVAC equipment performance, cost, maintenance, and energy efficiency for mega building projects.

Image Title:

Local vs Imported HVAC Equipment for Mega Projects

Conclusion: Choosing the Right HVAC Solution

Selecting between local and imported HVAC equipment requires balancing:

- Budget and upfront costs

- Long-term reliability and maintenance

- Energy efficiency and sustainability

YAOAN provides guidance and engineering support for optimizing equipment selection in mega projects, helping clients achieve performance, efficiency, and regulatory compliance.

FAQ – Local vs Imported HVAC Equipment

Is imported HVAC equipment always better?

Not necessarily. Imported systems often offer advanced features, but local systems may provide better support, faster parts availability, and lower TCO.

How to decide between local and imported systems?

Evaluate total cost of ownership, energy efficiency, maintenance, certification, and vendor support in relation to project goals.

Can hybrid systems improve project outcomes?

Yes. Combining local and imported components allows optimization of cost, performance, and maintenance flexibility.