Table of Contents

ToggleUnique Challenges of Mega Projects

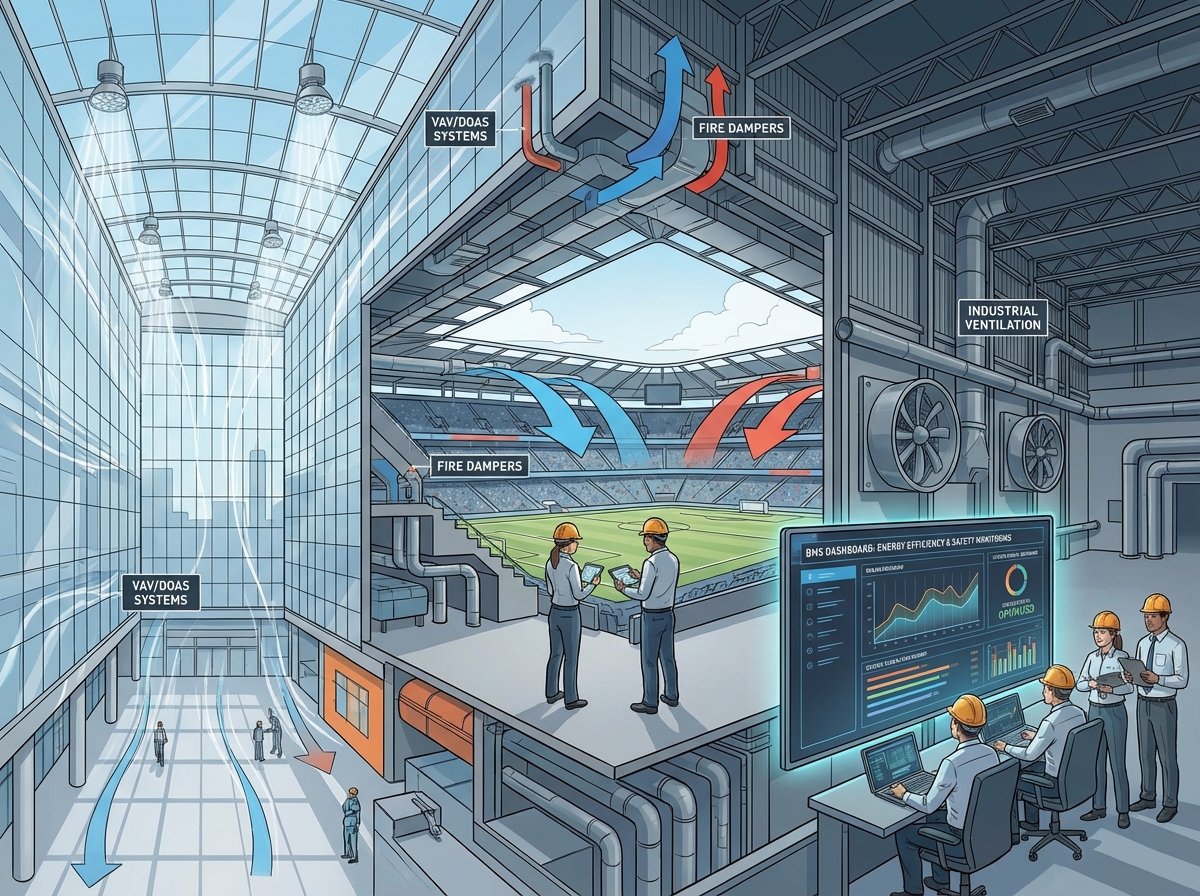

Mega projects—such as airports, hospitals, stadiums, and industrial complexes—pose complex HVAC challenges due to:

- Large volumes and varied occupancy

- Multiple zones with different environmental requirements

- Integration of fire and smoke safety systems

- Energy efficiency demands and sustainability goals

Proper planning and innovative solutions ensure system reliability, occupant comfort, and regulatory compliance.

Core Challenges and Solutions

Challenge 1: Large Volume Air Distribution

Problem: Maintaining uniform airflow in vast spaces like atriums, exhibition halls, or industrial bays can lead to drafts or stratification.

Solution:

- Use jet nozzle diffusers for long-throw, directional airflow

- Computational Fluid Dynamics (CFD) simulations to optimize diffuser placement

- Integrate VAV systems for zone-specific control

Challenge 2: Energy Efficiency and Cost Management

Problem: Mega projects consume substantial energy for HVAC operations, increasing operational costs.

Solution:

- Implement VAV or DOAS systems for adaptive airflow and temperature control

- Utilize heat recovery systems for exhaust air

- Integrate smart building automation for real-time energy monitoring

Challenge 3: Fire and Smoke Safety Integration

Problem: Large duct networks can allow rapid fire or smoke spread if not properly protected.

Solution:

- Install fire dampers at all fire-rated penetrations

- Coordinate smoke exhaust fans, emergency vents, and automatic sequences

- Ensure compliance with NFPA, EN, and local fire safety codes

Challenge 4: System Complexity and Coordination

Problem: Coordinating HVAC design with electrical, plumbing, and structural systems is challenging in mega projects.

Solution:

- Use BIM (Building Information Modeling) for integrated design

- Conduct multi-disciplinary coordination meetings

- Validate installation sequences and accessibility for maintenance

Challenge 5: Maintenance and Lifecycle Management

Problem: Hard-to-access equipment or poor documentation increases downtime and costs.

Solution:

- Design with maintenance accessibility in mind

- Schedule preventive maintenance for fans, dampers, and filters

- Implement lifecycle cost analysis for equipment replacement and upgrades

Design and Planning Best Practices

Load and Zone Analysis

- Accurately calculate heating, cooling, and ventilation needs per zone

- Consider occupancy variations and environmental conditions

Automated Control and Monitoring

- Implement BMS for airflow, temperature, and smoke control

- Predictive maintenance reduces failures and energy waste

Equipment Selection

- Choose fans, chillers, dampers, and diffusers based on zone requirements

- Prioritize energy efficiency, durability, and regulatory compliance

FAQ

What makes HVAC challenging in mega projects?

High volumes, multiple zones, energy efficiency requirements, and fire safety integration create complex design and operational challenges.

How can energy efficiency be improved in large HVAC systems?

By implementing VAV/DOAS systems, heat recovery, and smart building automation for adaptive control.

Why are fire dampers critical in mega projects?

They prevent fire and smoke from spreading through extensive duct networks, protecting occupants and property.

How does predictive maintenance help?

It reduces downtime, extends equipment life, and maintains energy efficiency through timely inspections and adjustments.

About YAOAN Ventilation

YAOAN Ventilation delivers engineered HVAC solutions for mega projects, combining energy-efficient airflow, fire and smoke safety, and intelligent building automation. Our systems ensure comfort, compliance, and cost-effective operation for airports, hospitals, stadiums, industrial complexes, and large commercial buildings.