As HVAC systems become more complex and buildings grow larger, traditional rule-based calculations alone are no longer sufficient to predict real airflow behavior. Computational Fluid Dynamics (CFD) has become a critical engineering tool for analyzing airflow, temperature distribution, pressure, and contaminant movement within buildings.

For architects, HVAC engineers, and B2B project stakeholders, CFD analysis bridges the gap between design intent and actual performance—especially in large, high-risk, or non-standard spaces.

Table of Contents

ToggleWhat Is CFD Analysis in HVAC Engineering

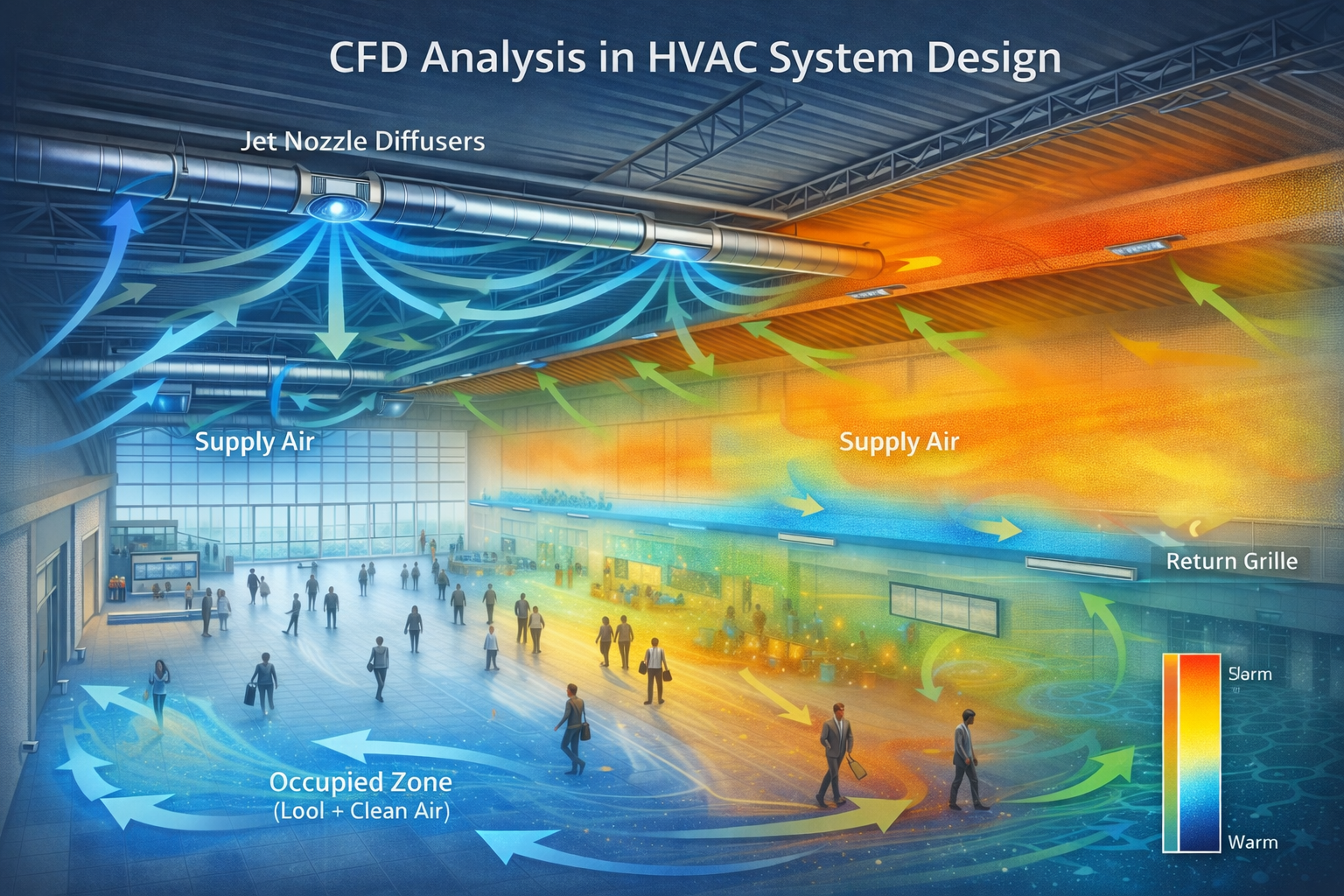

CFD analysis uses numerical methods to simulate how air moves, mixes, heats, cools, and transports contaminants within a defined space. In HVAC design, it allows engineers to visualize airflow patterns before construction.

Instead of relying solely on empirical assumptions, CFD models calculate:

- Air velocity fields

- Temperature gradients

- Pressure distribution

- Contaminant or smoke movement

This predictive capability makes CFD especially valuable for complex or high-volume environments.

Why CFD Matters in Modern HVAC Design

In large or unconventional buildings, airflow rarely behaves as assumed in simplified design methods. CFD helps identify issues that may not appear on drawings or spreadsheets.

Typical problems revealed by CFD include:

- Supply air failing to reach occupied zones

- Local drafts or stagnant zones

- Excessive temperature stratification

- Short-circuiting between supply and return

- Ineffective smoke exhaust paths

By addressing these risks early, CFD reduces costly redesigns and commissioning issues.

Key Applications of CFD in HVAC Projects

Airflow Distribution Optimization

CFD is widely used to evaluate diffuser placement, discharge angle, and airflow rate. Engineers can compare multiple air distribution strategies and select the most effective configuration.

This is particularly valuable in:

- Airport terminals

- Atriums and exhibition halls

- Industrial facilities

- Large open-plan commercial spaces

CFD visualizes whether supplied air actually reaches people—not just the ceiling void.

Thermal Comfort Assessment

Thermal comfort depends on more than temperature setpoints. CFD helps analyze:

- Air velocity at occupant level

- Vertical temperature gradients

- Radiant heat effects near façades

This allows designers to verify compliance with comfort standards and avoid complaints after handover.

Smoke Control and Fire Safety Design

In smoke management systems, CFD plays a critical role in validating fire and smoke scenarios.

Engineers use CFD to:

- Predict smoke spread paths

- Verify smoke exhaust efficiency

- Assess visibility and tenability levels

- Support compliance with EN, NFPA, and local fire codes

For large infrastructure and public buildings, CFD analysis is often reviewed by authorities having jurisdiction.

Indoor Air Quality and Contaminant Control

CFD can simulate the movement of pollutants, CO₂, or airborne particles. This is increasingly important in:

- Hospitals and healthcare facilities

- Laboratories and clean environments

- High-occupancy public buildings

By analyzing contaminant removal effectiveness, designers can improve ventilation efficiency without excessive air volume.

Typical HVAC Systems Evaluated Using CFD

CFD analysis is commonly applied to:

- Mixing ventilation systems

- Displacement ventilation systems

- Jet nozzle and long-throw diffusers

- VAV and demand-controlled ventilation

- Smoke exhaust and pressurization systems

Each system behaves differently, and CFD helps confirm whether theoretical advantages translate into real performance.

CFD Workflow in HVAC Design Projects

A typical CFD process includes:

- Geometry modeling based on architectural and MEP layouts

- Definition of boundary conditions (airflow, temperature, loads)

- Simulation under representative operating scenarios

- Visualization of airflow, temperature, and pressure fields

- Engineering interpretation and design optimization

CFD is most effective when integrated early in the design phase rather than used as a corrective tool.

Limitations and Engineering Judgment

While powerful, CFD is not a substitute for engineering expertise. Results depend heavily on:

- Input assumptions

- Boundary condition accuracy

- Model resolution and validation

CFD should support, not replace, sound HVAC engineering principles and real-world experience.

CFD as a Decision-Support Tool

CFD analysis transforms HVAC design from assumption-based planning into performance-driven engineering. When used correctly, it:

- Improves system reliability

- Enhances occupant comfort

- Supports energy-efficient design

- Reduces project risk

For complex and large-scale projects, CFD is no longer optional—it is part of responsible HVAC engineering practice.

FAQ Schema Content

What is CFD analysis in HVAC design?

CFD analysis simulates airflow, temperature, and pressure in buildings to predict HVAC system performance before construction.

When should CFD be used in HVAC projects?

CFD is recommended for large, complex, or high-risk spaces such as airports, atriums, industrial halls, and smoke control systems.

Does CFD replace traditional HVAC calculations?

No. CFD complements traditional methods by providing detailed airflow visualization and performance verification.

Is CFD required for fire and smoke control design?

In many large or critical projects, CFD is used to support compliance with fire safety regulations and authority reviews.

About YAOAN Ventilation

YAOAN Ventilation provides engineered airflow, ventilation, and fire protection solutions for complex buildings and infrastructure projects. By combining robust HVAC components with system-level engineering and CFD-supported design, YAOAN helps deliver reliable airflow control, safety compliance, and long-term operational performance.