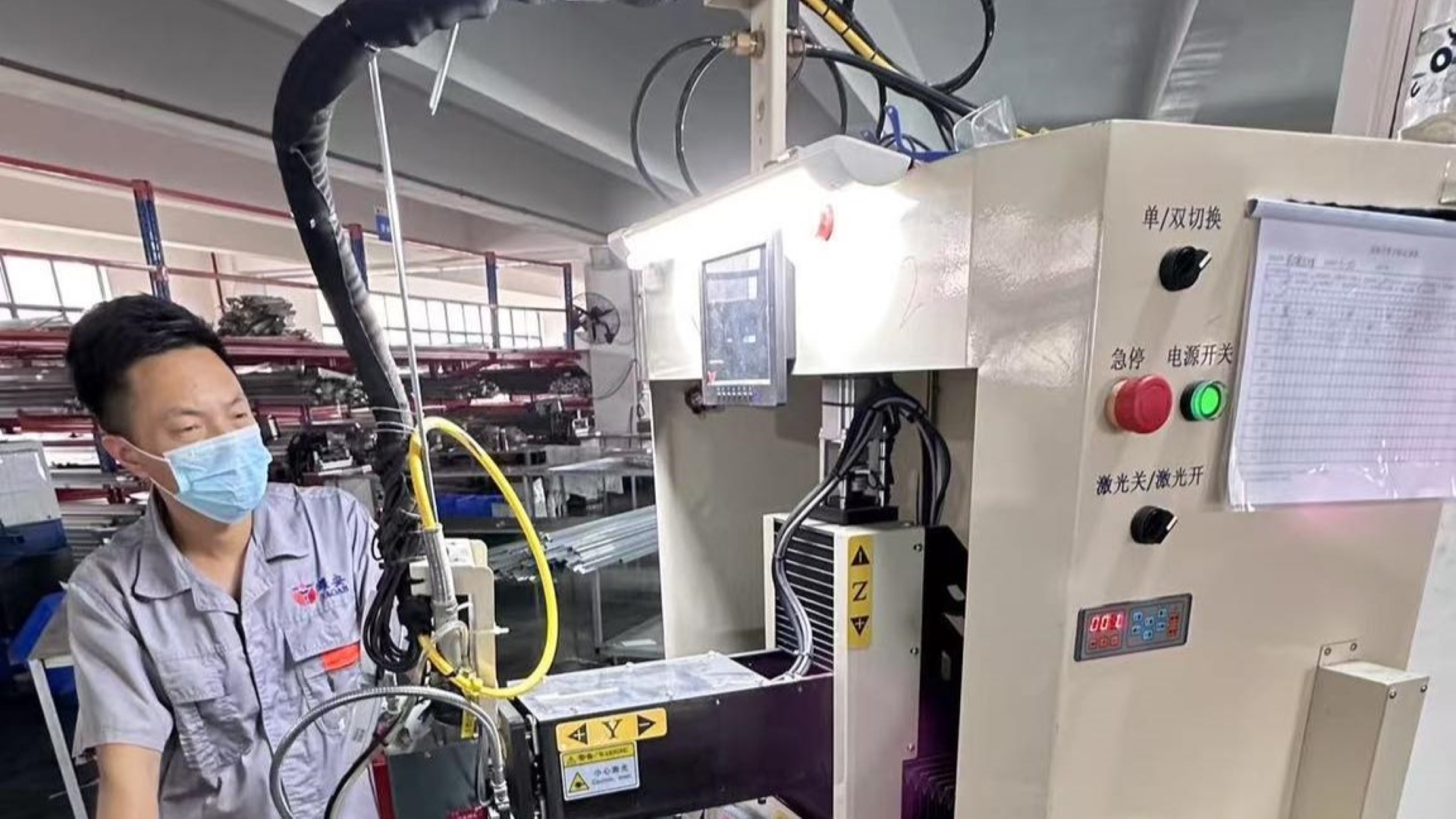

At YaoAn, excellence begins with precision. Our fire and ventilation equipment is manufactured using advanced laser welding technology, delivering welds that are not only structurally strong but visually flawless. Each seam is smooth, uniform, and free from deformation — a reflection of our commitment to engineering craftsmanship.

Laser welding offers significant advantages over traditional welding methods. It ensures deeper penetration, higher strength, and minimal heat distortion, which is critical for components such as fire dampers, smoke exhaust valves, silencers, and air ducts. With airtight sealing and enhanced durability, our products are built to perform in high-temperature and emergency environments.

Inside YaoAn’s factory, every welded component undergoes strict inspection to meet international safety standards, including ISO9001, CE, and fire protection certifications. By integrating automation and intelligent process control, we guarantee consistency across large-scale production without compromising precision.

Beautiful welds are not just about appearance — they represent reliability, safety, and long-term performance. With laser welding, YaoAn continues to set new standards in the fire protection and HVAC industry.