Table of Contents

ToggleIntroduction

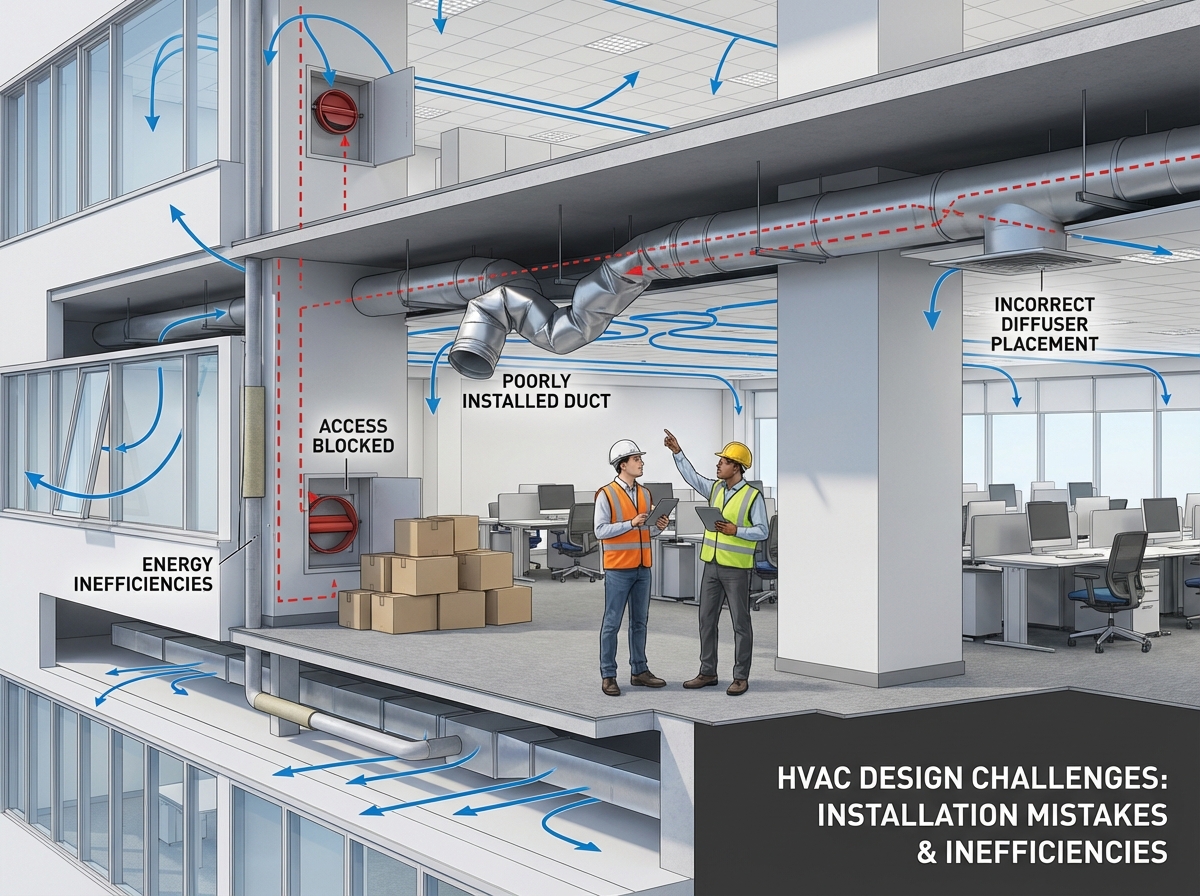

HVAC systems are critical for building comfort, safety, and efficiency. Mistakes in design or installation can cause:

- Uneven airflow and temperature distribution

- Increased energy consumption

- Fire and smoke safety risks

- Higher maintenance costs

Understanding common pitfalls helps engineers, designers, and contractors deliver reliable and efficient systems.

Common Mistakes and How to Avoid Them

Mistake 1: Inaccurate Load Calculations

Problem: Incorrect heating, cooling, or ventilation load calculations can lead to oversized or undersized equipment.

Solution:

- Conduct detailed load analysis using software and occupancy data

- Account for internal heat gains, solar exposure, and building envelope characteristics

Mistake 2: Poor Air Distribution

Problem: Improper diffuser placement or duct sizing results in drafts, hot/cold spots, and occupant discomfort.

Solution:

- Use CFD simulations to optimize airflow patterns

- Apply jet nozzle diffusers or VAV systems for large spaces

- Verify airflow on-site during commissioning

Mistake 3: Inadequate Fire and Smoke Safety Integration

Problem: Missing or incorrectly installed fire dampers and smoke exhaust systems compromise safety.

Solution:

- Ensure fire dampers are installed at all fire-rated penetrations

- Integrate smoke control fans and emergency sequences into building automation systems

- Follow NFPA, EN, and local code requirements

Mistake 4: Overlooking Maintenance Access

Problem: Poorly planned access to equipment increases downtime and operational costs.

Solution:

- Include adequate clearance around fans, dampers, and control panels

- Provide service platforms and removable panels for inspections and repairs

Mistake 5: Inefficient Energy Management

Problem: Using outdated systems or failing to implement adaptive controls increases energy costs.

Solution:

- Employ VAV, DOAS, and smart BMS systems

- Implement heat recovery and economizer strategies

- Monitor energy consumption and adjust system parameters dynamically

Best Practices for Successful HVAC Projects

Proper Planning and Coordination

- Align HVAC design with electrical, plumbing, and structural plans

- Use BIM for integrated design and clash detection

Regular Commissioning and Testing

- Test airflow, temperature, and pressure before handover

- Validate fire dampers, smoke exhaust, and emergency systems

Documentation and Training

- Provide detailed O&M manuals

- Train maintenance personnel on system operation, adjustments, and troubleshooting

FAQ

What are common HVAC design mistakes?

Inaccurate load calculations, poor airflow planning, neglected fire/smoke safety, insufficient maintenance access, and inefficient energy management.

How can energy efficiency be improved in HVAC systems?

By implementing VAV/DOAS systems, heat recovery, smart automation, and real-time energy monitoring.

Why is maintenance access important?

It allows preventive maintenance, reduces downtime, and ensures the system operates efficiently over its lifecycle.

How can fire safety be ensured in HVAC installations?

Through proper installation of fire dampers, smoke exhaust fans, emergency sequences, and compliance with codes and standards.

About YAOAN Ventilation

YAOAN Ventilation delivers expert HVAC solutions for large commercial, industrial, and infrastructure projects. Our systems combine efficient airflow, fire and smoke safety, energy optimization, and smart automation, helping projects achieve comfort, compliance, and cost-effective operation.