Table of Contents

ToggleCentrifugal Fans at the Heart of Airflow Systems

In most commercial and industrial HVAC plants, the main air movement comes from centrifugal fans. They sit inside air-handling units, extract stacks, and smoke-control systems, turning motor power into controlled AIRFLOW CONTROL and usable pressure.

Understanding how these fans work, how they differ by blade shape, and how to read their performance curves helps designers and operators match equipment to real project demands.

How a Centrifugal Fan Moves Air

A centrifugal fan draws air in along the shaft and throws it out radially. The housing or scroll then collects that flow and directs it into the duct system.

Inside the scroll:

- Air enters the eye of the impeller.

- Rotating blades add energy and push air outward.

- The casing converts part of the velocity into static pressure.

This radial flow path lets centrifugal fans handle higher pressures than many axial fans of similar size. That capability suits systems with long ducts, filters, and complex fittings.

Main Centrifugal Fan Types and Their Behavior

Blade shape defines how the fan handles pressure, efficiency, dirt, and power. Three families dominate HVAC and industrial ventilation work.

Forward-curved fans

Forward-curved blades bend in the direction of rotation. These fans typically:

- Deliver high flow at relatively low pressure.

- Run at lower speeds, which can help with sound in light-duty systems.

- Fit well into compact air-handling units and cabinet fans.

They work best in clean-air, low- to medium-pressure applications where efficiency and non-overloading are less critical than compact size and cost.

Backward-curved and airfoil fans

Backward-curved blades lean against the direction of rotation. Airfoil blades refine that shape further. These designs:

- Offer higher efficiency across a broad operating range.

- Tend to be non-overloading on power, which helps motor sizing.

- Suit medium- to high-pressure duct systems.

They serve as core workhorses in large AHUs, supply and return fans, and many smoke-control systems when selected for the right temperature ratings.

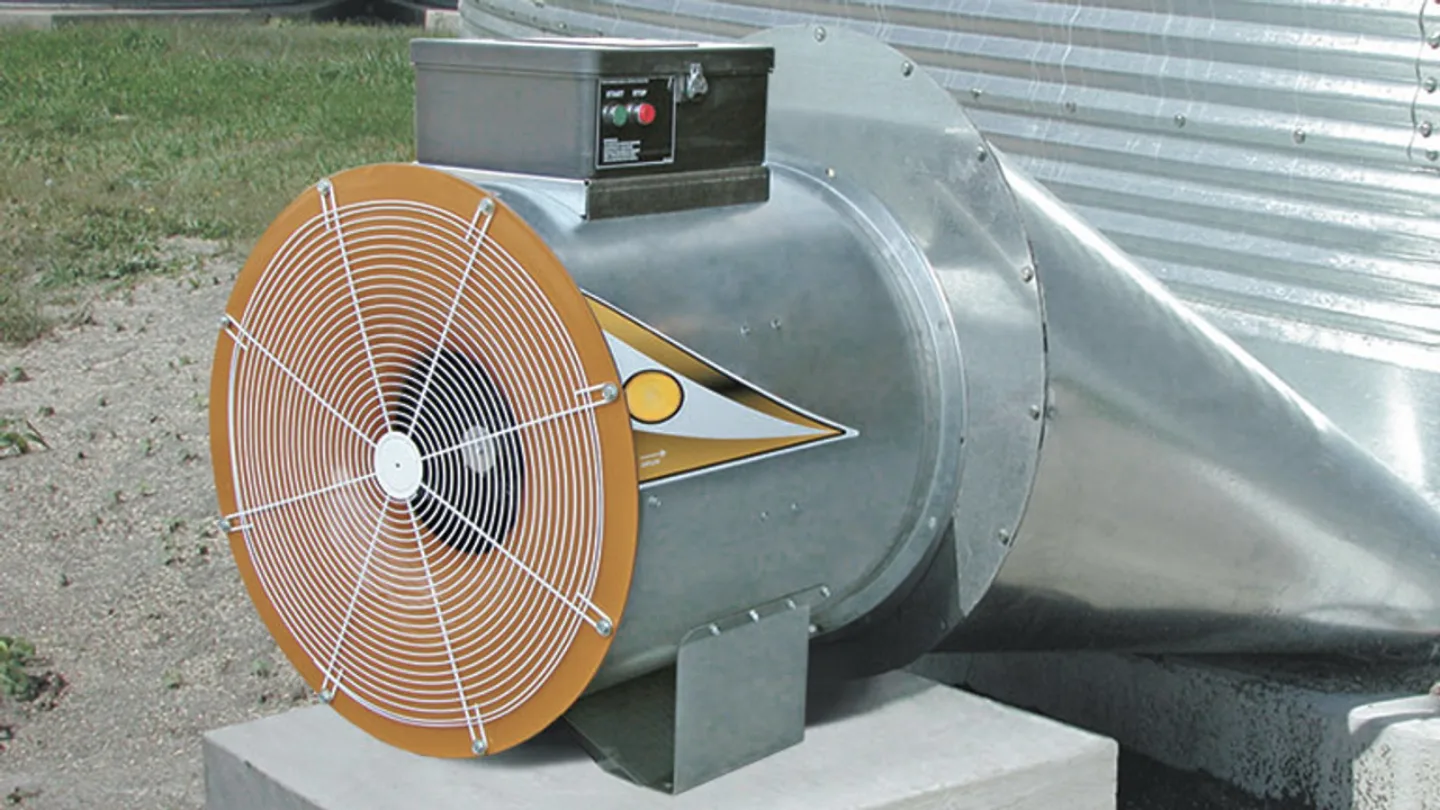

Radial and industrial duty fans

Radial fans use straight or near-straight blades. They generally:

- Tolerate dust, fibers, and abrasive particles better than airfoil shapes.

- Develop higher pressures for the same wheel diameter.

- Sacrifice some efficiency in exchange for ruggedness.

Engineers apply them in industrial exhaust, dust collection, kitchen extract, and other harsh environments where blade wear and fouling present greater risk.

Reading Centrifugal Fan Performance Curves

Fan curves link airflow, pressure, power, and efficiency at a defined air density. Selecting fans without reading those curves closely invites unstable operation.

Key elements on a typical curve include:

- Volume vs pressure – Shows how static or total pressure changes as flow increases.

- Efficiency bands – Mark regions where the fan converts shaft power into useful pressure most effectively.

- Brake horsepower or kW lines – Indicate power demand at each point.

Designers place the duty point in a stable region that offers good efficiency, acceptable noise, and margin for system changes such as filter loading.

System resistance curves add another layer. Where the fan curve intersects the system curve, the fan actually operates. If dampers or duct layouts change, that intersection shifts, and so does power draw and noise.

Selecting a Centrifugal Fan for a Project

A structured selection process keeps choices consistent and traceable.

Typical steps:

- Define duty – Airflow, required pressure, temperature, air density, and any contamination.

- Choose fan type – Forward-curved, backward-curved, airfoil, or radial based on duty and environment.

- Read curves – Find the model that meets duty at a good efficiency point with acceptable BHP.

- Check noise – Confirm sound levels and plan for attenuation if needed.

- Confirm construction – Materials, coatings, bearings, and drive arrangements that fit the application.

For smoke-control or high-temperature use, engineers add requirements such as certified temperature ratings and specific run durations under fire conditions.

Centrifugal Fans vs “Normal” Fans

Many people think of “normal fans” as small axial or propeller units that move air with low pressure. Compared to these:

- Centrifugal fans handle higher system resistance and longer duct runs.

- They support filtration, heat recovery, coils, and dampers without falling out of their working range.

- Their scroll housings and blade shapes give more options for acoustic performance and duct connection.

Axial fans still provide value in high-flow, low-pressure settings such as tunnels and condenser decks. The choice between axial and centrifugal fans depends on pressure, layout, and FIRE SAFETY or process demands rather than on a simple “better or worse” judgment.

Applications Across HVAC and Fire Safety

Centrifugal fans appear wherever systems need stable pressure and controlled distribution. Typical uses include:

- Supply and return fans in central AHUs.

- Stair and lobby pressurization units designed to work with dampers and pressure controls.

- Smoke extract fans in car parks, malls, and industrial halls.

- Process exhaust where filters, scrubbers, or energy-recovery devices sit in the air path.

In each case, fan selection must match not only normal operation but also worst-case conditions. That includes blocked filters, damper positions during fire mode, and possible changes in building use.

FAQ

What is a centrifugal fan?

A centrifugal fan is an air-moving machine that draws air in axially and discharges it radially. It uses rotating blades and a scroll casing to generate pressure and move air through ductwork, filters, and other HVAC components.

What is the difference between centrifugal fan and normal fan?

Compared with a simple axial or propeller fan, a centrifugal fan handles higher pressures and more complex systems. It sends air out sideways through a scroll, supports longer duct runs and filtration, and often gives designers more control over efficiency and noise.

What are the advantages of centrifugal fans?

Centrifugal fans provide strong pressure capability, stable performance across a range of flows, and good compatibility with filters and duct systems. They can achieve high efficiency in many HVAC and industrial applications and adapt to different air qualities through blade shape and material choices.

When to use a centrifugal fan?

Engineers choose centrifugal fans when systems need significant static pressure, such as central air-handling plants, smoke exhaust risers, industrial exhaust, and process ventilation with filters or energy-recovery devices. They also use them when duct runs are long or layouts are complex.

What are the disadvantages of centrifugal fans?

Centrifugal fans tend to be bulkier than axial fans for the same flow and can require more space for scrolls and outlets. Some types cost more and may generate higher sound levels at certain conditions. Incorrect selection or poor inlet conditions can lead to unstable operation and wasted energy.

What is another name for a centrifugal fan?

Many people refer to centrifugal fans as blower fans or simply blowers, especially in industrial and process contexts. The terms describe the same basic radial-flow concept.

What are the three types of centrifugal fans?

Common groupings list forward-curved, backward-curved or backward-inclined (including airfoil), and radial-blade centrifugal fans as three major types. Each type matches different combinations of efficiency, pressure, dirt tolerance, and acoustic behavior.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our centrifugal fan portfolio covers forward-curved, backward-curved, airfoil, and radial designs, supported by clear performance curves, BHP data, and construction options for both comfort and smoke-control duty. By aligning fan selection with real system resistance, control strategies, and FIRE SAFETY requirements, YAOAN VENTILATION helps projects achieve stable AIRFLOW CONTROL, efficient energy use, and long-term reliability across the full life cycle of each installation.