Table of Contents

ToggleAuto/Manual as the “Second Layer” of Control

In a modern HVAC or smoke-control system, most equipment runs under automatic control from the BAS or local controller. Even so, every critical fan, damper, and pump still needs a way to override that logic when something abnormal happens.

That backup path usually takes the form of an AUTO/MANUAL switch or selector mode. It lets operators hand control back and forth between programmed logic and direct human action without losing awareness of the system state.

How Auto/Manual Logic Works in HVAC Controls

At its core, Auto/Manual is a mode decision. The system reads the selector position first, then decides whose command it should follow.

- In AUTO, the controller uses schedules, setpoints, interlocks, and safety logic.

- In MANUAL, a human operator drives the output directly within defined limits.

For a fan starter, the logic often looks like:

- AUTO – Start/stop from BAS or local controller, subject to safeties.

- MAN – Run the fan on operator demand, still honoring key safety trips (overload, emergency stop).

Good design prevents manual mode from bypassing fundamental protections, especially on smoke-control, tunnel, or car-park systems.

Interlocks and feedback

An Auto/Manual scheme ties to:

- Status feedback (running, fault, position)

- Alarms when someone selects MANUAL on critical equipment

- BAS graphics that show active mode clearly

Operators then see both what the device is doing and who is in charge: program or person.

Typical Applications in Ventilation and Smoke Control

Fan and pump starters

Most motor control centers for ventilation include a HAND–OFF–AUTO (HOA) selector. Common uses:

- Supply and exhaust fans in air-handling plants

- Smoke-control and stair-pressurization fans

- Chilled and condenser water pumps that support air systems

In normal operation, all sit in AUTO and follow BAS schedules and interlocks. During testing, commissioning, or fault-finding, technicians move to HAND (manual) to prove rotation, measure current, or hold a fan on while they observe system response.

Dampers and actuators

Fire and smoke dampers use automatic signals for most conditions. In some designs, control panels include:

- Auto/manual for smoke dampers in car parks or tunnels

- Manual position selectors (open/close) for test modes

- Clear indication of commanded and actual position

These features support FIRE SAFETY tests and emergency procedures, while automatic logic still takes over when the system returns to normal.

Local panels and plantroom controls

Large air-handling units and ventilation plants often have local panels with:

- Selector switches for Auto/Manual per fan or section

- Local start/stop pushbuttons active in Manual mode

- Indication lamps for run, fault, and mode

This arrangement lets technicians work in the plantroom even when the BAS workstation sits far away.

Ways to Implement Auto/Manual Switching

Hardwired selector switches

The simplest version uses a physical selector wired into the control circuit:

- In AUTO, output comes from a control relay or analog signal.

- In MAN, output bypasses that path and feeds a fixed or adjustable signal directly.

For on/off devices (fans, simple dampers), this can be a straightforward contact arrangement. For modulating outputs, designers may use hand–auto stations with manual potentiometers or local controllers.

Software-based mode selection

In more advanced BAS systems, operators select Auto/Manual from a screen instead of a physical switch. The controller:

- Interprets the mode flag

- Chooses between automatic output and an operator-entered value

- Logs mode changes and duration for traceability

This approach reduces panel hardware but still needs clear indication and proper security so only authorized staff can change modes.

Combined approaches

Many critical installations use both:

- Hardware selector for local override and safety

- Software mode indication and control for remote operation

The design must define which has priority and how conflicts resolve, so technicians do not fight the BAS unintentionally.

Design and Safety Considerations

Protecting people and equipment

Manual control never means “no protection.” Even in MAN mode, the system should still:

- Respect overloads, trips, and emergency stops

- Honor hardwired interlocks that protect structure and occupants

- Prevent operation in clearly unsafe conditions (for example, known reverse rotation on smoke fans)

For life-safety functions, engineers document which safeguards remain active in Manual and test them regularly.

Clarity for operators

Confusing Auto/Manual schemes cause mistakes. Good practice includes:

- Clear labels on switches and panel facias

- BAS graphics that show Auto/Manual mode in plain language

- Alarms when critical equipment stays in Manual longer than allowed

O&M manuals from YAOAN VENTILATION and other suppliers should describe the exact mode behavior for each control panel.

Commissioning and handover

During commissioning, teams use Manual mode heavily. After testing, they must:

- Return all devices to AUTO before leaving the site

- Record any equipment that must remain manual with reasons and time limits

- Train facility staff on how and when to use Manual appropriately

This discipline prevents “temporary” overrides from becoming permanent hidden changes to AIRFLOW CONTROL.

FAQ

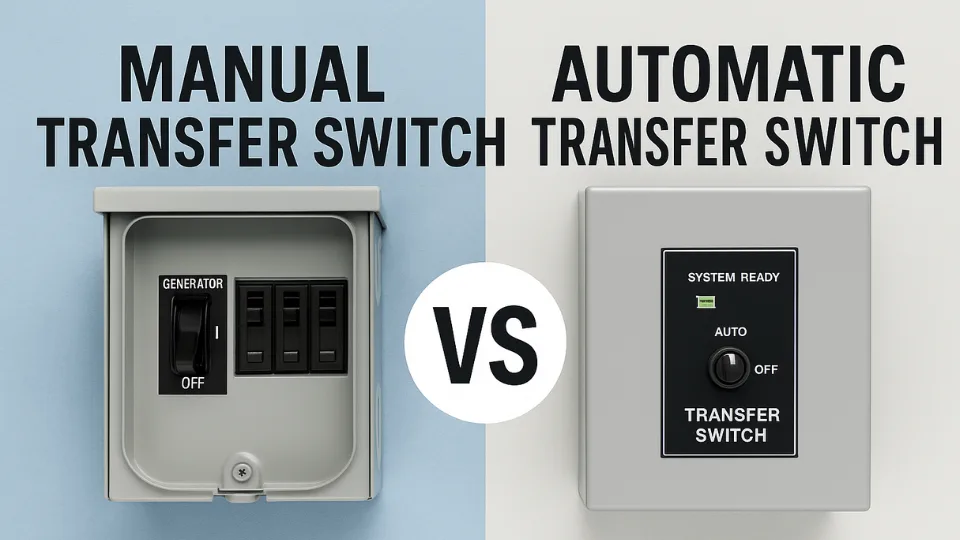

What is an auto manual selector switch?

An auto manual selector switch lets operators choose whether a device follows automatic control logic or a direct manual command. In HVAC work, it appears on fan starters, pump panels, and some damper controls, and it decides whether the BAS or a person drives the output at any given moment.

What does auto manual mean?

“Auto/Manual” describes two modes of operation. Auto means the controller or BAS decides when and how the equipment runs based on schedules and interlocks. Manual means an operator sets the command directly, usually for testing, maintenance, or temporary override, while core safety protections still stay in force.

What does “manual switch” mean?

A manual switch is a physical or software control that a person operates by hand. In ventilation systems, it can start or stop a fan, move a damper, or select a mode. The key feature is that a human, not a program, initiates the action and can see the effect immediately.

What is the use of auto switch?

An auto switch allows equipment to run under automatic logic instead of manual control. When in Auto, fans, dampers, and pumps respond to signals from thermostats, pressure sensors, time schedules, or fire systems. This mode delivers consistent operation, energy management, and coordinated behavior across the HVAC system.

What happens when a transmission range sensor goes bad automatically?

In vehicles, a faulty transmission range sensor can cause incorrect gear indication, harsh shifting, or failure to start in the expected range. The control system may enter a protective mode. Drivers should have automotive issues like this diagnosed and repaired by qualified technicians, as the fault lies outside building HVAC controls.

What are the benefits of a manual switch?

Manual switches give technicians control during commissioning, troubleshooting, and special operating conditions. They allow direct verification of rotation, airflow, and responses without waiting for automatic logic. When used carefully, they speed up diagnosis and provide a safe fallback if automation or communication networks fail.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our products—fans, dampers, smoke-control components, silencers, and precision aluminum ventilation parts—integrate with control panels and BAS architectures that use clear Auto/Manual strategies. By combining reliable equipment with sound control design, YAOAN VENTILATION helps projects maintain safe override options, stable AIRFLOW CONTROL, and predictable behavior in both normal and emergency operation.