Table of Contents

ToggleAcoustic Louvers in Real HVAC Projects

When outside air enters a building, noise often tries to enter with it. Mechanical yards, busy streets, and powerful fans all create sound that can pass straight through conventional openings. Acoustic louvers give designers a way to admit airflow while reducing that noise path.

They sit in walls, intake screens, equipment yards, and rooftop screens. In each location, they balance three needs: airflow capacity, acoustic attenuation, and weather protection.

How Acoustic Louvers Control Sound

An acoustic louver looks similar to an architectural louver, but the blade profile and internal construction do a different job.

Blade geometry and internal absorption

Most acoustic louvers rely on:

- Shaped blades that force sound to reflect multiple times

- Sound-absorbing linings inside the blades or baffle cores

- Non-parallel paths that disrupt direct line-of-sight from source to receiver

As air passes through, sound energy hits absorbent surfaces. The material converts a portion of that energy into small amounts of heat, which reduces the sound level that reaches the interior.

Airflow and pressure drop

No louver works as a “free opening.” Acoustic baffles narrow the path and increase pressure drop. That extra resistance affects:

- Fan selection and static pressure

- Air intake sizing

- Energy use over the life of the system

Design teams must account for this pressure drop early so the louver can deliver both noise control and stable AIRFLOW CONTROL.

Performance Indicators for Acoustic Louvers

Acoustic performance always depends on frequency. A product that works well at mid frequencies may offer less benefit at very low or very high frequencies.

Key metrics include:

- Insertion loss (dB) – Reduction in sound level as noise passes through the louver

- Octave-band data – Attenuation broken down by frequency band

- Static pressure drop at rated face velocity

- Free area ratio and recommended face velocity range

Specifications should ask for octave-band insertion loss, not only a single-number rating, so the design can match the louver to the dominant noise spectrum.

Where Acoustic Louvers Add Value

Mechanical rooms and air intakes

Mechanical rooms often sit close to occupied spaces. Acoustic louvers at outside air and relief openings can:

- Reduce fan and motor noise radiated to neighbors or adjacent rooms

- Allow natural intake and exhaust where ducts would be complex

- Support compliance with local noise ordinances

They work especially well at AHU intakes, generator rooms, and large exhaust plenums.

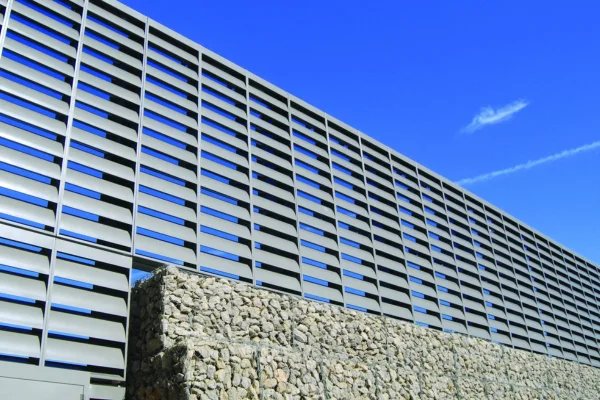

Rooftop and yard screening

Around rooftop units or ground-mounted equipment, acoustic louvers can combine visual screening with noise control. When engineered correctly, these screens:

- Hide equipment from view

- Reduce sound levels at property lines

- Maintain adequate ventilation for heat rejection and combustion air

Designers must coordinate structural supports, wind loads, and maintenance access along with the acoustic targets.

Facade integration

On some projects, acoustic louvers appear directly in the facade. They allow natural or hybrid ventilation into specific spaces while controlling environmental noise from outside. Careful detailing keeps water and wind-driven rain from reaching interior finishes.

Selection Considerations for Designers and Contractors

Define the acoustic target first

Selection starts with a clear noise goal:

- Maximum sound level at nearby receivers (rooms or property lines)

- Dominant noise source and its spectrum

- Any regulatory or project-specific limits

With those inputs, the engineer can estimate the required insertion loss and compare product data to see which louver families fit.

Match louver size to airflow and fan capability

For each candidate louver, check:

- Required face area at design airflow

- Static pressure drop at that velocity

- Impact on fan duty and energy use

If pressure drop climbs too high, options include increasing louver area, selecting a different profile, or relocating the louver to reduce duct losses.

Consider materials, durability, and hygiene

Acoustic louvers must survive the same environment as the building envelope:

- Galvanized or coated steel for general exterior use

- Aluminum for lighter weight and corrosion resistance

- Stainless steel for aggressive or coastal environments

Internal absorbent materials should resist moisture, fiber erosion, and microbial growth. Protective facings or perforated metal skins help keep insulation stable over time.

Coordinate with FIRE SAFETY and maintenance

In some locations, acoustic louvers sit near fire-resistance–rated walls, smoke-control paths, or egress routes. The design must ensure:

- Any required fire dampers or smoke dampers work correctly with the louver

- Access remains available for inspection and cleaning

- Combustibility of internal materials meets local requirements

Coordination drawings and O&M manuals should show louver positions, access routes, and maintenance instructions clearly.

FAQ

What is an acoustical louver?

An acoustical louver is a ventilation louver that integrates sound-absorbing baffles or blades. It allows air to pass while reducing noise transmission between the noisy side and the quiet side. Designers use it at intakes, exhausts, and equipment screens where both airflow and noise control matter.

What is the purpose of acoustic insulation?

Acoustic insulation aims to reduce sound transmission or reverberation. It can absorb noise inside a space, block noise between rooms, or dampen vibration within assemblies. In ventilation systems, acoustic insulation in ducts and louvers helps manage fan and airflow noise so occupied areas stay within comfort and regulatory limits.

What is the purpose of a louver?

A louver allows air to enter or leave a space while blocking rain, debris, and direct views. It uses angled blades to shield openings from the elements. In HVAC design, louvers often sit at outside air intakes, exhaust points, and mechanical enclosures, where they support both airflow and weather protection.

Do louvers reduce noise?

Standard louvers offer limited noise reduction and mainly handle airflow and rain. Acoustic louvers specifically include sound-absorbing elements and blade geometries that reduce sound transmission. When properly selected and sized, they can noticeably cut noise from fans, mechanical rooms, or exterior sources.

What are the disadvantages of acoustic insulation?

Acoustic insulation can add cost, thickness, and weight to assemblies. Some products reduce available space or complicate cleaning and inspection. If designers choose the wrong material, issues such as moisture retention, fiber shedding, or durability concerns can appear, especially in outdoor or high-humidity environments.

What is the difference between acoustic and normal insulation?

Normal insulation focuses on thermal performance, while acoustic insulation targets sound control. Some materials address both, but acoustic products use specific densities, facings, and configurations to absorb or block sound. In louvers and ducts, acoustic insulation usually sits behind perforated metal to expose absorbent surfaces to the sound field.

Why is it called a louver?

The word “louver” traces back to terms for slatted or shuttered openings used to vent smoke and heat while keeping out rain. Modern louvers follow the same principle: angled blades that create a controlled path for air. Acoustic versions evolve that idea by adding sound-absorbing features to the traditional form.

What are the disadvantages of louvers?

Louvers reduce free area and create pressure drop, which increases fan effort. They can admit noise if not designed for acoustics, and poorly detailed units may allow water penetration or dirt buildup. Maintenance access can also be challenging if louvers sit in hard-to-reach locations without proper platforms or doors.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our portfolio includes fans, acoustic components, fire and smoke dampers, silencers, and precision-built aluminum ventilation parts, all designed to coordinate with building facades and shaft layouts. By pairing carefully selected acoustic louvers with robust AIRFLOW CONTROL strategies, YAOAN VENTILATION helps projects manage noise, protect comfort, and maintain reliable, code-compliant performance over the full system life.