Table of Contents

ToggleThe Role of As-built Drawings in HVAC Projects

As-built drawings record how the HVAC system was actually installed, not how it was originally designed. They capture every significant change made during construction.

Owners, facility teams, and future designers use these documents to understand duct routes, equipment locations, and control points long after the project closes. Reliable as-built drawings reduce risk during maintenance, upgrades, and emergency work.

For HVAC, accurate as-built sets support:

- System troubleshooting and fault isolation

- Code and fire-safety inspections

- Future capacity increases or retrofits

- Clear coordination with electrical, plumbing, and fire protection systems

What an HVAC As-built Drawing Set Should Include

As-built requirements vary by project, but most HVAC packages follow a clear logic: show what exists, where it sits, and how it connects.

System routing and layout

A complete HVAC as-built set normally documents:

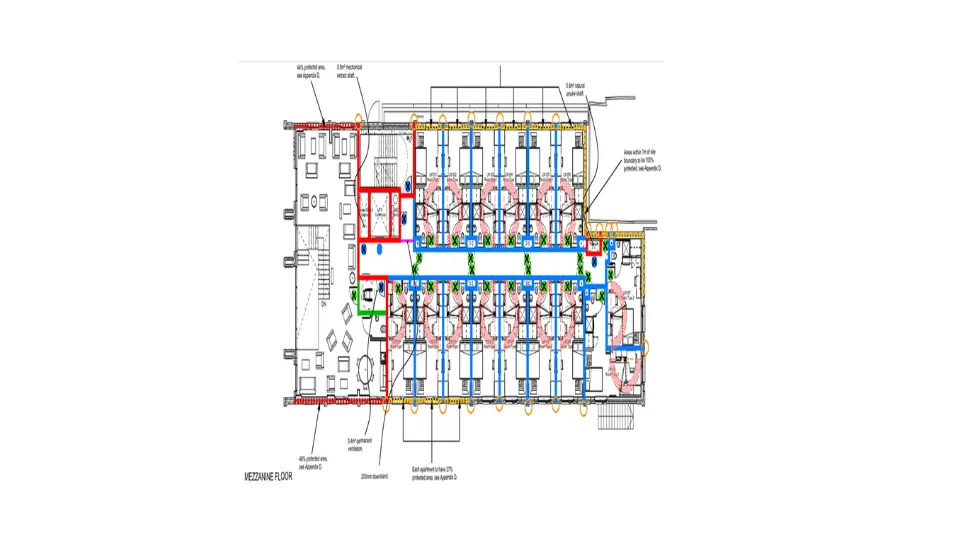

- Final ductwork routes, sizes, elevations, and materials

- Supply, return, and exhaust duct paths, including shafts and risers

- Locations and sizes of outdoor air intakes and relief/exhaust outlets

- Penetrations through fire-rated walls, floors, and shafts

These details help fire-safety teams evaluate FIRE SAFETY separation, smoke movement risks, and access for inspection.

Equipment, terminals, and devices

Beyond duct lines, the drawings should show:

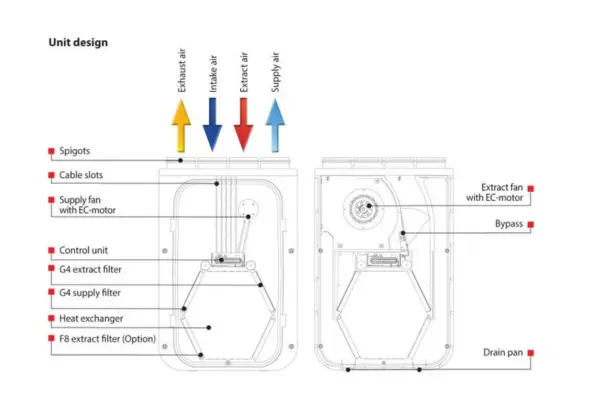

- Air handling units, fan coil units, fans, and air-cleaning devices

- Fire dampers, smoke dampers, backdraft dampers, and access doors

- VAV boxes, diffusers, grilles, and specialty terminals

- Control devices such as sensors, actuators, and control panels

Each item should carry a consistent tag that matches schedules, control diagrams, and the BAS naming convention. Tag consistency makes diagnostics faster and safer.

Design changes and coordination notes

During construction, equipment often shifts to avoid clashes or to improve access. As-built drawings should clearly mark:

- Deviations from the original construction drawings

- Revised duct sizes or routes due to coordination

- Changes to equipment models, capacities, or control sequences

- Any field-approved value engineering modifications

Clear notation reduces confusion and shows why the final installation differs from the design intent.

How Contractors Develop Accurate HVAC As-built Drawings

Good as-built drawings start in the field, not in the CAD or BIM office. Site teams need a simple, disciplined process.

Capturing field changes

Typical practices include:

- Marking up printed drawings with redlines as work progresses

- Recording elevation changes, offsets, and re-routed branches

- Updating equipment tags and locations when substitutions occur

- Coordinating with other trades before finalizing changes

The project team then transfers these redlines into the digital model or CAD files, with clear revision history.

Using BIM and digital tools

On many projects, the fabrication or coordination model becomes the base for as-built documents. The HVAC contractor or BIM coordinator:

- Updates the model with final field conditions

- Confirms that hanger locations, clearances, and access zones match reality

- Exports updated plans, sections, and 3D views for the as-built set

Digital workflows shorten review time and support later use in asset management platforms or digital twins.

Submission, Review, and Handover of As-built Drawings

As-built drawings form a key part of project closeout. They link construction work to long-term operation.

Typical submission sequence

A common HVAC process looks like this:

- The installing contractor completes field redlines and digital updates.

- The contractor submits HVAC as-built drawings to the main contractor or construction manager.

- The design engineer and owner’s representative review the set against site conditions.

- After comments are addressed, the team issues an approved as-built package.

That approved set then supports O&M manuals, testing and balancing reports, and commissioning records.

Integration with commissioning and O&M

Before handover, the project team should align:

- As-built HVAC drawings

- Air and water balancing reports

- Control schematics and points lists

- Equipment submittals and maintenance instructions

When these documents line up, facility teams can locate components quickly, understand AIRFLOW CONTROL strategies, and maintain compliance with fire and mechanical codes through the building’s life.

FAQ

What is meant by as-built drawings?

As-built drawings are the final record of how a project was actually constructed. They show the real locations, sizes, and connections of equipment and services after all field changes. In HVAC, they document the installed ductwork, piping, controls, and equipment so owners and technicians can safely operate and modify the system.

What are as-built drawings examples?

Examples of as-built drawings include updated HVAC floor plans showing final duct routes, riser diagrams with true pipe sizes, and equipment layouts that match installed unit positions. Elevations, sections, and detail views may also appear, each revised to reflect actual clearances, access panels, fire dampers, and penetrations in the completed building.

What is the difference between construction drawing and as-built drawing?

Construction drawings show the design intent and guide installation before work starts. As-built drawings record what the team actually installed after design changes, coordination adjustments, and site decisions. In many projects, the as-built set becomes the legal and technical reference for future maintenance, renovations, and safety reviews.

Who is responsible for as-built drawings?

The installing contractor usually prepares the as-built drawings for their trade, based on field conditions and redlines. The general contractor or construction manager coordinates the overall package. Design engineers and the owner’s representative review and accept the final set, since they will rely on the documents for long-term system operation.

When to submit as-built drawing?

As-built drawings are typically submitted during project closeout, after installation, testing, and balancing are complete. Contractors should keep redlines current throughout construction, then finalize and submit the updated drawings near substantial completion. Many contracts set specific deadlines for as-built approval before final payment or handover.

What are the benefits of as-built drawings?

As-built drawings help owners and facility teams understand how systems actually run through the building. They improve safety during maintenance, speed up troubleshooting, and reduce the risk of damaging hidden services during renovations. Accurate as-built information also supports compliance reviews, future upgrades, and better planning for capacity or layout changes.

How to check as-built drawings?

To check as-built drawings, reviewers walk the site and compare visible installations with the documents. They confirm equipment tags, duct and pipe routes, valve locations, and access points. Any mismatch is noted and corrected. Cross-checks with test reports, control diagrams, and schedules help ensure the final set reflects the real HVAC system.

What is the purpose of an as-built survey?

An as-built survey measures and verifies the actual location and configuration of building elements after construction. For HVAC, a survey confirms key elevations, routes, clearances, and penetrations. The results feed into the as-built drawings so the final documents match physical conditions and support safe operations, inspections, and future modifications.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our product range includes fans, fire dampers, smoke control components, silencers, and precision-built aluminum ventilation parts, each manufactured to strict national standards and supported by rigorous documentation. By combining reliable equipment with clear drawings and technical support, YAOAN VENTILATION helps projects maintain code compliance, protect life safety, and operate HVAC systems with long-term confidence.