Table of Contents

ToggleFan Coil Units in Building HVAC Systems

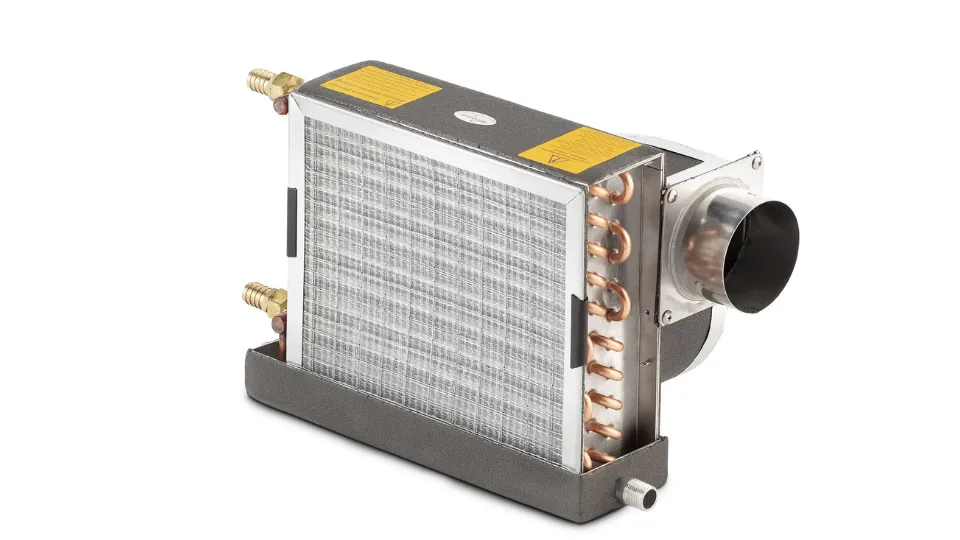

A fan coil unit, or FCU, is a terminal device that uses a fan and a water coil to condition air in a specific room or zone. It recirculates indoor air across a chilled-water or hot-water coil, then delivers cooled or heated air directly into the space.

FCUs handle local temperature and sometimes humidity control. They work best as part of a broader HVAC strategy that also includes central fresh air supply and exhaust systems for ventilation and pressure management.

Core Components and Operating Principle

A typical FCU includes:

- Fan that pulls room air into the unit and pushes conditioned air back to the space

- Water coil connected to chilled-water and/or hot-water piping

- Filter that captures dust from recirculated air

- Drain pan and piping to remove condensate during cooling

- Controls such as a thermostat, valve actuator, and fan-speed selection

During cooling, the FCU fan draws warm room air across the chilled-water coil. Heat transfers from the air to the water, and moisture can condense on the coil. The unit then delivers cooler, drier air back into the room. During heating, hot water flows through the coil and warms the recirculated air.

Two-pipe, Four-pipe, and Control Options

FCUs appear in several hydronic configurations:

- Two-pipe systems use one supply and one return line that switch seasonally between hot and chilled water.

- Four-pipe systems provide separate hot and chilled water circuits, which allow simultaneous heating and cooling in different zones.

Local controls adjust water valves and fan speed to match the room load. This zoning flexibility makes FCUs popular in hotels, offices, and residential towers where occupants expect individual temperature control.

How FCUs Work with Central Fresh Air Systems

An FCU primarily recirculates room air; it does not usually provide the required outdoor air for ventilation by itself. Central fresh air systems supply the outdoor air needed to dilute indoor contaminants, handle building pressurization, and support indoor air quality.

Fresh Air Delivery Strategies

Designers typically combine FCUs with one of these fresh air approaches:

- Dedicated outdoor air system (DOAS) that conditions and delivers outdoor air to each zone through separate ductwork

- Central air handling unit (AHU) that supplies mixed and filtered outdoor air to FCU zones via small duct branches or corridor grilles

- Makeup air units for corridors and common areas, while FCUs handle zone-level thermal loads

The fresh air may enter the room through ceiling diffusers, corridor undercuts, or a duct connection to the FCU plenum. The key goal is simple: the FCU manages temperature, and the central system delivers properly filtered, conditioned outdoor air.

Coordinating Airflow and Pressure Control

When FCUs and central fresh air systems operate together, the design team needs consistent AIRFLOW CONTROL and pressure balance:

- Supply fresh air in quantities that meet code ventilation rates for each occupancy type.

- Use transfer paths between rooms and corridors so fresh air can move through the building.

- Coordinate FCU operation with building automation so pressure relationships in critical spaces stay stable.

In many projects, the central fresh air system also handles deeper filtration and energy recovery, while FCUs handle local comfort loads with minimal ductwork.

Role of Exhaust and Return Systems with FCUs

Fresh air and exhaust form a pair. As outdoor air enters, exhaust or relief air must leave. FCUs recirculate room air, but they do not typically exhaust air to outdoors.

Exhaust in Bathrooms, Kitchens, and Service Areas

Separate exhaust systems protect indoor air quality by removing:

- Moisture from bathrooms and showers

- Odors from kitchens or pantries

- Heat and contaminants from service spaces

These exhaust systems maintain negative pressure in designated areas so contaminants do not migrate to cleaner zones. Fresh air units and FCUs then supply make-up air and temperature control to the occupied rooms.

Maintaining Overall System Balance

Balanced design links:

- Central fresh air intake

- Exhaust and relief fans

- FCU recirculation airflow

If maintenance teams adjust FCU fan speeds, exhaust rates, or fresh air dampers without coordination, they can disrupt pressure relationships. A well-integrated system keeps airflow predictable, supports indoor comfort, and helps protect building occupants.

Fan Coil Units vs Air Handling Units

An FCU and an air handling unit (AHU) both condition air, but they serve different levels of the HVAC system.

Functional Differences

- Fan coil unit (FCU)

- Serves a single room or small zone

- Recirculates local air through a water coil

- Usually has minimal or no direct outdoor air connection

- Air handling unit (AHU)

- Serves larger areas or entire floors

- Mixes, filters, and conditions outdoor and return air

- Typically connects to a duct system with supply and return branches

In many buildings, the AHU or DOAS provides ventilation air and filtration, while FCUs handle zone-level cooling and heating. This division reduces duct complexity while still meeting code ventilation requirements.

Where FCUs Fit Best

FCUs fit well in:

- Hotels and apartments that need individual room control

- Office zones with varied schedules and loads

- Retrofit projects where new ductwork is difficult to install

In each case, FCUs still rely on coordinated fresh air and exhaust strategies to maintain indoor air quality and moisture control.

Operation, Maintenance, and Reliability

Routine Service Needs

Keeping FCUs clean and functional supports both comfort and hygiene. Typical service tasks include:

- Cleaning or replacing filters

- Flushing coils and checking for fouling or corrosion

- Inspecting drain pans and condensate lines for clogs or leaks

- Verifying valve operation and thermostat calibration

- Checking fan motors, belts (if used), and bearings

Many facilities schedule FCU inspections at least once a year, with more frequent filter service in dusty or high-load environments.

Common Performance Issues

If a fan coil unit underperforms, technicians often find:

- Dirty filters and coils that reduce airflow and heat transfer

- Blocked condensate drains leading to water leakage

- Noisy fans from worn bearings or imbalanced impellers

- Sticking valves that prevent proper hot or chilled water flow

- Control issues that lead to temperature swings or poor dehumidification

Proactive maintenance and clear documentation help prevent nuisance complaints and protect equipment life.

FAQ

What are fan coil units connected to?

Fan coil units connect to chilled-water and often hot-water piping that comes from central plant equipment such as chillers and boilers. They also connect to electrical power, local controls, and a condensate drain. In many designs, a separate central system supplies fresh air to the zones served by the FCUs.

What are common problems with fan coil units?

Common FCU problems include clogged filters, dirty coils, and blocked condensate drains. These issues reduce airflow, cause poor temperature control, or lead to water leakage. Technicians also encounter noisy fans, failing motors, and control faults that create hot and cold spots or inconsistent comfort in occupied spaces.

Does air handling unit and fan coil mean the same thing?

No. An air handling unit is a central piece of equipment that conditions and distributes air through ductwork, usually mixing outdoor and return air. A fan coil unit is a terminal device that recirculates air in a specific zone and uses a water coil for heating or cooling. FCUs depend on separate systems for most ventilation air.

What is the purpose of fan coil units?

The purpose of fan coil units is to provide localized heating and cooling for individual rooms or small zones. They recirculate indoor air across a water coil and deliver conditioned air close to occupants. This zoning helps match comfort to actual use patterns while limiting the amount of ductwork required in the building.

What are common FCU problems?

Frequent FCU issues include reduced airflow from dirty filters, poor heat transfer due to fouled coils, and condensate leaks from blocked drains. Noise from worn fan components and incorrect control settings can also cause complaints. Regular inspection, cleaning, and testing help prevent these problems and maintain stable performance.

What is the difference between FCU and AHU?

An FCU serves a single space or small zone and relies on water coils for cooling and heating. It mainly recirculates local room air. An AHU serves larger areas, mixes outdoor and return air, and usually includes higher-level filtration and sometimes humidity control. FCUs often work downstream of AHUs or dedicated outdoor air systems.

How often should a fan coil unit be serviced?

Most buildings service fan coil units at least once per year, with more frequent filter changes based on dust levels and operating hours. High-use or critical areas may follow a semiannual or quarterly schedule. The goal is to keep airflow, cleanliness, and drainage within design limits to protect comfort and system reliability.

What is the purpose of an FCU?

An FCU’s main purpose is to control temperature at the room or zone level through recirculated air and a hydronic coil. It allows individual spaces to respond to changing occupancy and internal loads without reconfiguring central duct systems. This zoning improves comfort and supports flexible building use.

Can FCU work without AHU?

An FCU can operate and provide local heating or cooling without an AHU, as long as it receives hot or chilled water from a plant. However, the building still needs a strategy for fresh air and exhaust. That ventilation may come from a dedicated outdoor air system, separate makeup air units, or other central fans rather than a traditional AHU.

About YAOAN VENTILATION

YAOAN VENTILATION delivers optimized air and airflow management solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and fire protection systems for commercial buildings, infrastructure, and specialized environments. Our product line includes fans, fire dampers, smoke control components, silencers, and precision-built aluminum ventilation parts, each manufactured to strict national standards and verified through rigorous quality testing. With dependable performance, integrated support for fresh air and exhaust strategies, and a commitment to long-term safety, YAOAN VENTILATION helps projects combine FCUs and central ventilation into stable, compliant, and efficient HVAC systems.