Table of Contents

ToggleUnderstanding HEPA Filtration in Building Systems

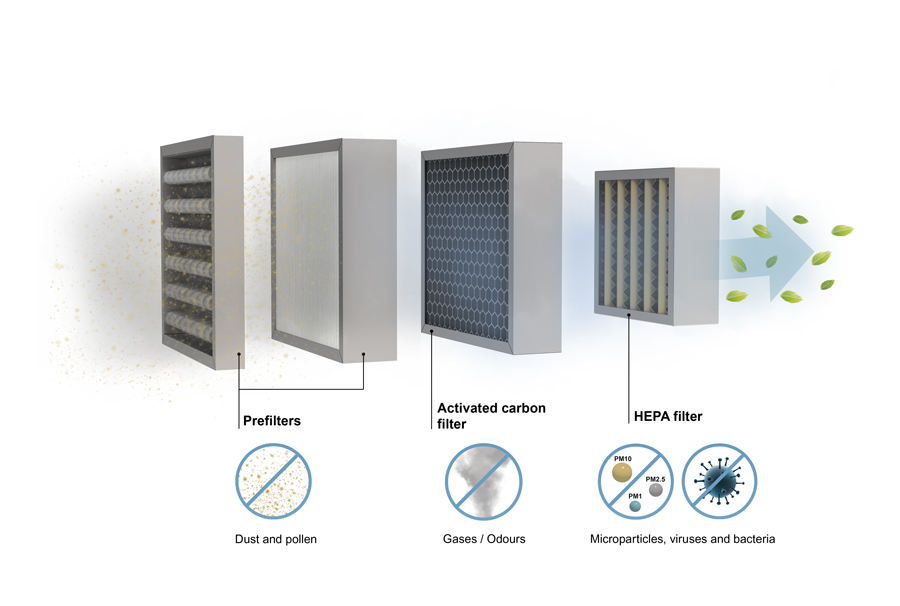

High-efficiency particulate air (HEPA) filters are critical components in HVAC systems where air cleanliness and infection control matter. They remove fine particles that standard filters cannot capture.

In cleanrooms, hospitals, laboratories, and pharmaceutical plants, HEPA filters help protect people, processes, and products. They support cleaner supply air, reduce contamination risk, and contribute to a safer built environment.

HEPA filtration is not a decorative upgrade. It is a functional safety measure for airborne containment and controlled environments.

Efficiency Classes and Standards for HEPA Filters

HEPA filters are defined by their ability to capture very small particles at a specified efficiency. In many international standards, HEPA filters must capture at least 99.95% or 99.97% of particles at the most penetrating particle size, often around 0.3 microns.

Common reference points include:

- HEPA efficiency: 99.95–99.97% at test particle size

- Higher grades (e.g., ULPA): Up to 99.9995% for ultra-clean environments

- MERV vs. HEPA: High-MERV filters improve filtration but still do not reach true HEPA performance

Project teams should verify which local or international standards apply, such as EN 1822 or IEST recommended practices, and confirm that the selected HEPA grade aligns with the cleanliness classification of the space.

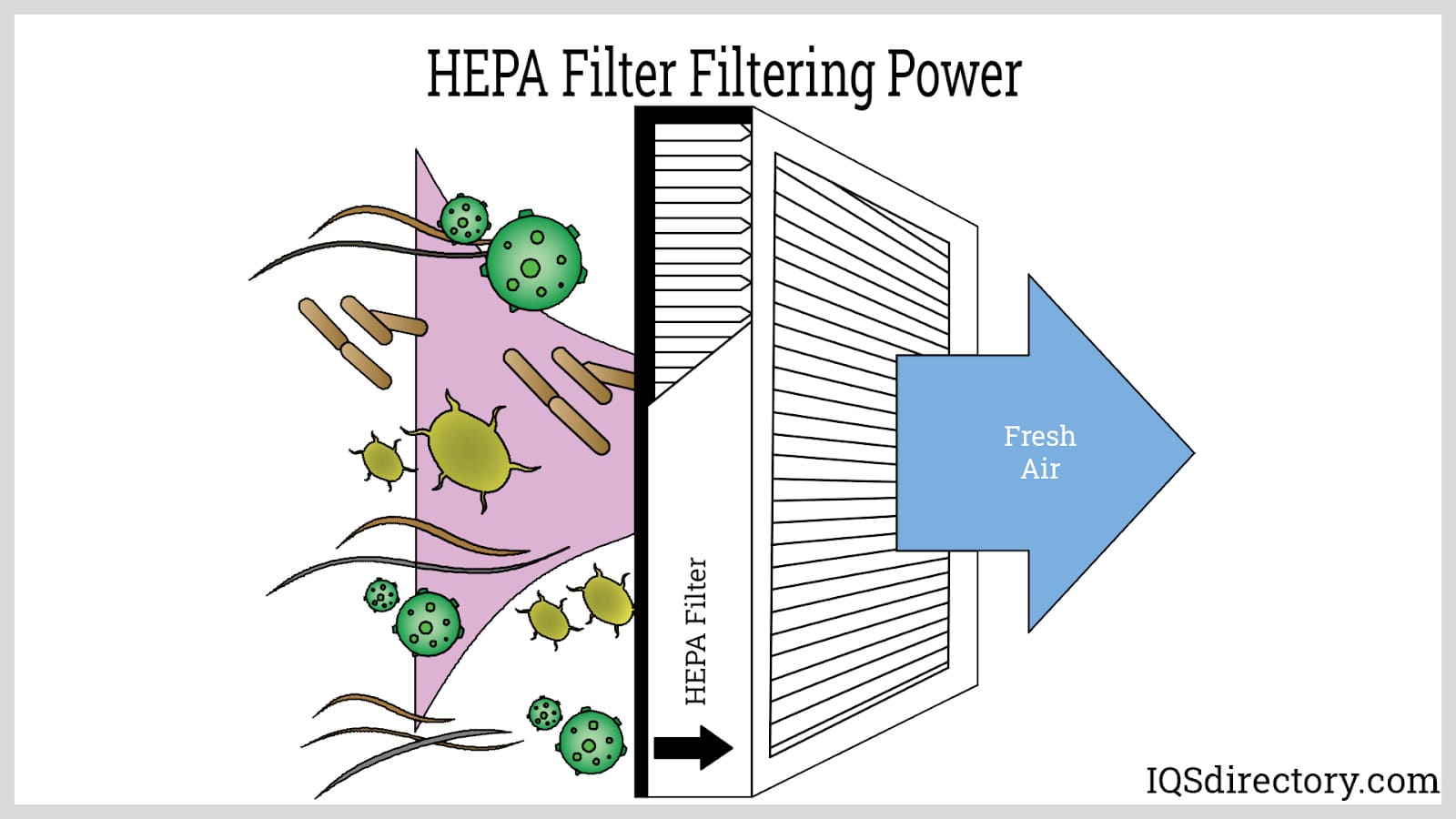

How HEPA Filters Capture Particles

HEPA filters do not work like simple screens. They combine several physical mechanisms to capture particles of different sizes and behaviors. The media usually uses dense glass fibers or synthetic fibers formed into a deep pleated structure.

Key capture mechanisms include:

- Inertial impaction: Larger particles deviate from airflow and collide with fibers

- Interception: Medium particles follow airflow but touch and stick to fibers

- Diffusion: Very small particles move randomly (Brownian motion) and hit fibers

- Electrostatic effects (in some media): Charges help attract and hold particles

Because of these mechanisms, HEPA filters are most challenged at a specific “most penetrating” particle size, not the smallest particles. Correct test methods focus on this range to validate real performance.

Critical Applications in Cleanrooms and Healthcare

Cleanrooms and Controlled Environments

In cleanrooms, HEPA filters help achieve ISO cleanliness classes by limiting airborne particles that can damage products or processes. They are usually installed in:

- Terminal HEPA supply units in ceilings

- Fan filter units above critical zones

- Return or exhaust paths for sensitive processes

They protect semiconductor wafers, pharmaceuticals, optics, and medical devices from particulate contamination that can cause defects, reduced yields, or regulatory noncompliance.

Hospitals, Isolation Rooms, and Operating Theaters

In healthcare, HEPA filters support infection control strategies by reducing airborne pathogens. They are used in:

- Operating rooms and procedure suites

- Isolation rooms for airborne infectious diseases

- Protective environments for immunocompromised patients

- Specialized exhaust systems for laboratories and treatment areas

In these spaces, HEPA filters support pressure differentials and directional airflow patterns. They work together with ventilation layouts, air changes per hour, and pressure monitoring to maintain safe conditions for patients and staff.

Installation and Replacement Best Practices

Correct installation is essential for HEPA performance. Even a high-grade filter will not protect a facility if it leaks around the frame or housing.

Good practice includes:

- Using rigid, well-sealed housings compatible with HEPA frames

- Installing gaskets or gel seals specified by the filter manufacturer

- Torqueing fasteners evenly to prevent bypass

- Coordinating filter orientation with airflow direction markers

Replacement intervals depend on dust loading, run time, and required cleanliness level. Many facilities change HEPA filters when pressure drop reaches a defined limit or when performance tests indicate loss of efficiency.

Maintenance, Monitoring, and Common Mistakes

HEPA filters require proactive maintenance planning. They cannot be treated like low-cost prefilters.

Recommended steps:

- Monitor differential pressure across the filter to track loading

- Perform periodic leak testing (e.g., aerosol scanning) in critical spaces

- Inspect housings and seals for mechanical damage or deformation

- Change prefilters regularly to extend HEPA service life

Common mistakes include oversizing or undersizing filters, ignoring pressure drop until airflow collapses, or replacing HEPA filters without re-testing. Another frequent issue is installing “HEPA-like” filters without documented certification or test data.

HEPA Filters in the Context of Building Safety and Ventilation

HEPA filters sit within a larger AIRFLOW CONTROL strategy. They work with fans, duct layouts, dampers, and control systems to manage both cleanliness and comfort.

In some facilities, HEPA systems integrate with smoke control and emergency ventilation design. While HEPA filters are not fire dampers, they can influence pressure relationships, exhaust paths, and system response during emergencies. The overall HVAC design must consider filter pressure drop, fan sizing, redundancy, and access for safe replacement.

For building owners and managers, the key questions are:

- Does the selected HEPA rating match the risk and regulatory requirements?

- Is the system designed to maintain airflow under expected loading?

- Are test, maintenance, and replacement procedures clear and documented?

When these points are addressed, HEPA filtration becomes a stable, predictable layer of protection in the building’s environmental control strategy.

FAQ

What is a HEPA filter used for?

A HEPA filter is used to remove fine airborne particles such as dust, aerosols, bacteria, and some viruses from the air stream. It is commonly applied in cleanrooms, hospitals, laboratories, and other critical spaces where air cleanliness directly affects safety, product quality, or infection control.

What is the difference between a HEPA filter and a normal filter?

A HEPA filter is engineered to capture at least 99.95–99.97% of particles at a defined test size, often around 0.3 microns. Typical “normal” HVAC filters have lower efficiency and mainly remove larger dust. HEPA filters offer much higher particle removal but require careful design, sealing, and fan capacity.

What are the two disadvantages of HEPA filters?

Two key disadvantages are higher pressure drop and higher cost. HEPA filters are dense, so fans must work harder and may need more power or larger capacity. They also cost more than standard filters and require specialized housings, testing, and replacement procedures to keep performance reliable and safe.

Is Dyson a HEPA filter?

Dyson is an equipment brand, not a filter type. Some Dyson air purifiers or vacuums use HEPA-grade or HEPA-style filters, but the device itself is not a HEPA filter. Users should check the product documentation to confirm whether the installed cartridge meets recognized HEPA efficiency standards.

Is it good to sleep with a HEPA filter?

Using a HEPA-equipped air purifier in a bedroom can improve air cleanliness by reducing fine particles, allergens, and some biological aerosols. For many people, this supports better comfort and respiratory health. The device should be sized correctly for the room, maintained properly, and operated at a safe noise level.

How long do HEPA filters last?

Service life depends on dust load, airflow rate, and operating hours. In cleanroom or hospital systems, HEPA filters may last from one to several years under controlled conditions. Facilities usually change them when pressure drop exceeds a set limit or when periodic testing shows reduced performance or leakage.

Can you wash a HEPA filter?

Most HVAC-grade HEPA filters used in cleanrooms and hospitals are not washable. Washing can damage the media, open leakage paths, or remove electrostatic properties. They are designed as disposable components. Only filters explicitly labeled as washable should be cleaned, and even then, performance must be verified.

How do I know if my HEPA filter is bad?

Signs of a bad HEPA filter include abnormal pressure readings, visible damage, or failed leak tests. In critical environments, technicians use aerosol scanning or other validation methods to confirm integrity. For consumer devices, poor airflow, unusual noise, or reduced air quality may indicate that the filter needs replacement.

Can a HEPA filter help with allergies?

Yes. HEPA filters can reduce airborne allergens such as fine dust, pollen, pet dander, and some mold spores. By lowering the concentration of these particles, they often support better comfort for allergy-sensitive occupants. For best results, HEPA filtration should be combined with regular cleaning and moisture control in the space.

YAOAN VENTILATION delivers optimized air and particle control solutions backed by nearly three decades of engineering experience. Since 1996, we have focused on industrial-grade ventilation and air protection systems for commercial buildings, infrastructure, and specialized environments. Our portfolio includes high-performance filtration units, fire and smoke control components, and precision-built aluminum ventilation parts—each produced to strict national standards and verified through rigorous quality testing. With dependable performance, technical support, and a commitment to long-term safety, YAOAN VENTILATION helps projects achieve stable system operation, reliable cleanliness, and consistent compliance.